headline bars

continuation tabs

notes

warnings

model no. 054-8259-0 | contact us 1.800.689.9928

17

16

geNeRAL CUTTINg

1. Make sure that the workpiece is firmly clamped to prevent the workpiece from moving while cutting.

2. Use the appropriate type and size of blade for the workpiece material and size.

3. Check for clearance behind the workpiece so that the blade will not impact another surface.

4. Clearly mark the line of cut.

5. Hold the saw firmly. Make sure to keep your hand on the insulated gripping areas only.

6. Use the variable speed dial to set the speed. Turn on the jigsaw and bring it to the maximum desired

cutting speed before applying the blade to the workpiece.

7. Do not force the tool. Keep the shoe plate flat against the workpiece while cutting. Use only enough steady

pressure on the blade to keep the saw cutting.

8. Reduce pressure as the blade comes to the end of the cut.

9. Allow the saw to come to a complete stop before removing the blade from the workpiece.

10. If sawing fiberglass, plaster, wallboard, or spackling compound, clean the saw motor vents frequently with

a vacuum or compressed air. Always wear safety goggles when cleaning tools using compressed air.These

materials are highly abrasive and may accelerate the wear on motor bearings and brushes.

MeTAL CUTTINg

When cutting metal, clamp the material down. Be careful to move the saw along slowly. Use lower speeds.

Do not twist, bend, or force the blade. If the saw jumps or bounces, use a blade with finer teeth. If the blade

seems clogged when cutting soft metal, use a blade with coarser teeth.

For easier cutting, lubricate the blade with a stick of cutting wax, if available, or cutting oil when cutting steel.

Thin metal should be sandwiched between two pieces of wood or tightly clamped onto a single piece of wood

(wood on top of the metal). Draw the cut lines or design on the top piece of wood.

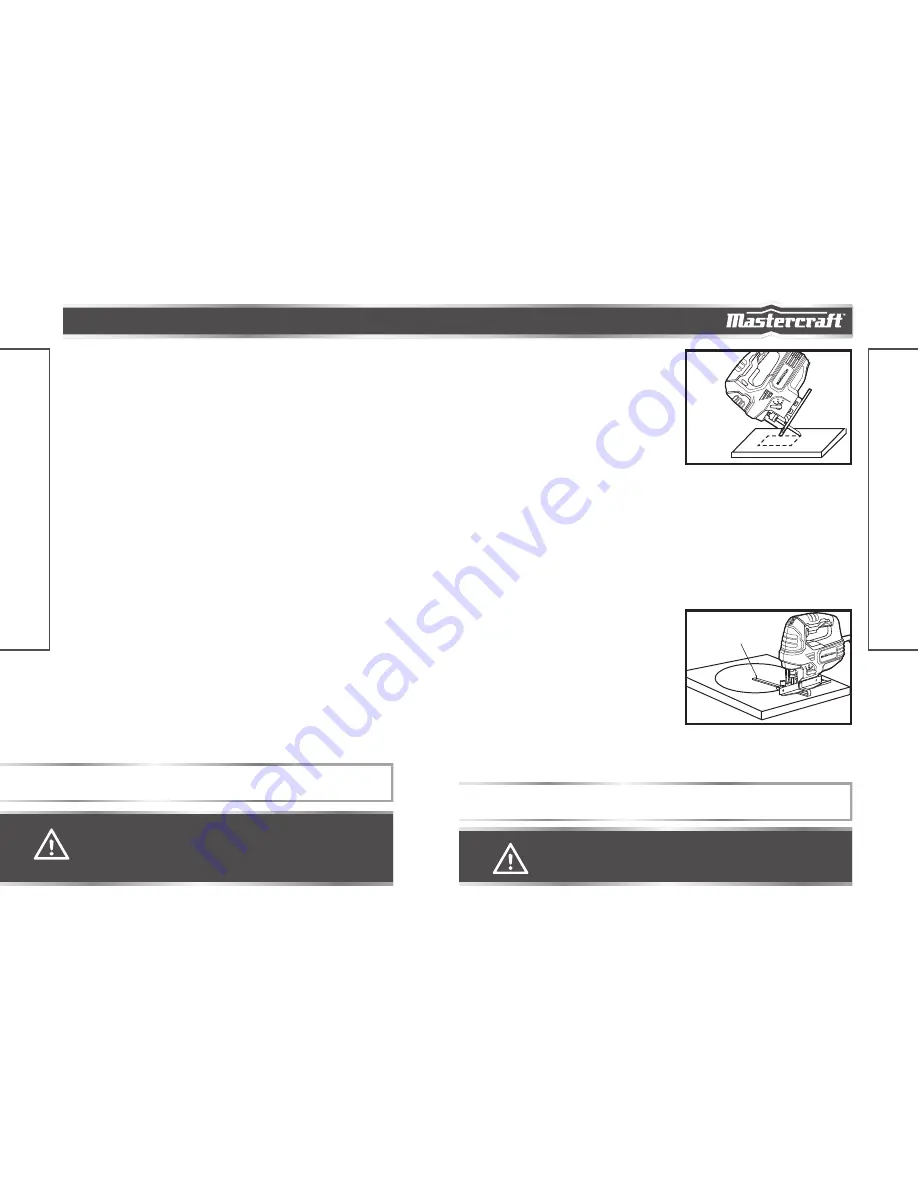

PLUNge CUTTINg (

(fig 12)

Plunge cutting is useful and time-saving for making

rough openings in soft materials. It makes it unnecessary

to drill a hole for an inside or pocket cut.

1. Draw cutting lines for the opening.

2. Hold the saw firmly and tilt it forward so the toe of

the shoe plate rests on the workpiece.

3. Make sure that the blade is well clear of the

workpiece.

4. With the toe of the shoe plate held firmly against the workpiece to prevent side wobble, start the saw and

then gradually lower the blade into the workpiece..

5. When the blade touches the workpiece, continue pressing down on the toe of the shoe plate.

6. Slowly pivot the saw like a hinge until the blade cuts through the workpiece and the shoe plate rests flat

on the workpiece.

7. Then begin sawing in the usual manner along the cut line.

CUTTINg CURVeS

Curved cuts can be made with the jigsaw by guiding the direction of the cut with pressure applied on the saw.

CUTTINg A CIRCLe

(fig 13)

1. Before attaching the edge guide, draw a circle and drive a

finishing nail into the workpiece at the centre of the circle.

2. Drill or plunge cut near the circle’s edge.

3. Turn the saw off and disconnect the plug from the power

source.

4. Attach the edge guide to the saw with the edge

guide facing “up”.

5. The distance from the finishing nail to the blade

should be equal to the circle radius.

6. Insert the plug into the power source, hold the saw firmly, squeeze the trigger and slowly push the saw

forward. To make a hole, cut from inside the circle. To make wheels or discs, cut from the outside.

wARNINg!

• Do not allow familiarity with the saw to make you careless.

• Always securely clamp and support the workpiece. Always maintain proper control of the

jigsaw. Failure to clamp and support the workpiece and loss of control of the saw could

result in serious injury.

FPO

OPERA

TING

INSTRUCTIONS

OPERA

TING

INSTRUCTIONS

NOTICe:

Always apply a steady, firm, downward pressure on the front of the saw as you cut. This will keep

the saw blade from jumping out of the workpiece.

fig 12

fig 13

Finishing nail

wARNINg!

•

Do not try to plunge cut into hard materials, such as steel.

FPO

NOTICe:

Cut slowly so the blade will stay straight in the cut. Place small wedges in the cut to keep the

inner circle from spreading when near the end of the cut.

Summary of Contents for 054-8259-0

Page 13: ......