7

Fuel level

– the tank should be at least half full.

Oil level

– the oil level must be between the lower and upper marks.

Air filter

– replace any damaged parts.

Starting up

Prior to operating the submersible pump, the drive engine should have the correct operating

temperature (warm up for 2-3 minutes). Then switch the engine back off again.

Open the fuel tap by moving the fuel ON/OFF lever fully to the right.

If starting the engine from cold, set the choke ON by moving the choke lever fully to the left. If

restarting a warm engine, the choke is usually not required. However, if the engine has cooled to a

degree, partial choke may be required.

Turn the engine ON/OFF switch clockwise to the

“1” position.

Set the throttle to the idle position by moving the throttle lever fully to the right.

Do not start the engine on full throttle, as the compactor will

vibrate as soon as the engine starts.

Taking a firm hold of the control handle with one hand, grasp the

recoil starter handle with the other. Pull the recoil starter until

engine resistance is felt, then let starter return.

Taking care not to pull the starter

’s cope fully out, pull the starter

handle briskly.

Repeat until the engine fires.

Once the engine fires gradually, set the choke lever to the OFF position by moving it to the right.

To stop

Set the throttle to idle and turn the engine ON /OFF

switch anticlockwise to the “0” position to stop

the engine. Then turn the fuel off.

SERVICE & MAINTENANCE

Maintenance and repair work must be carried out only to the extent described in this manual.

Before carrying out maintenance or repair work, switch off the engine and allow it to cool down. For

petrol-powered engines, you must pull off the spark plug connector.

Cleaning

Always keep the unit clean and be sure to clean it each time you have finished

using it. Clean the engine cooling fins when the engine has cooled down. Do not

use gasoline or solvents. Danger of explosion!

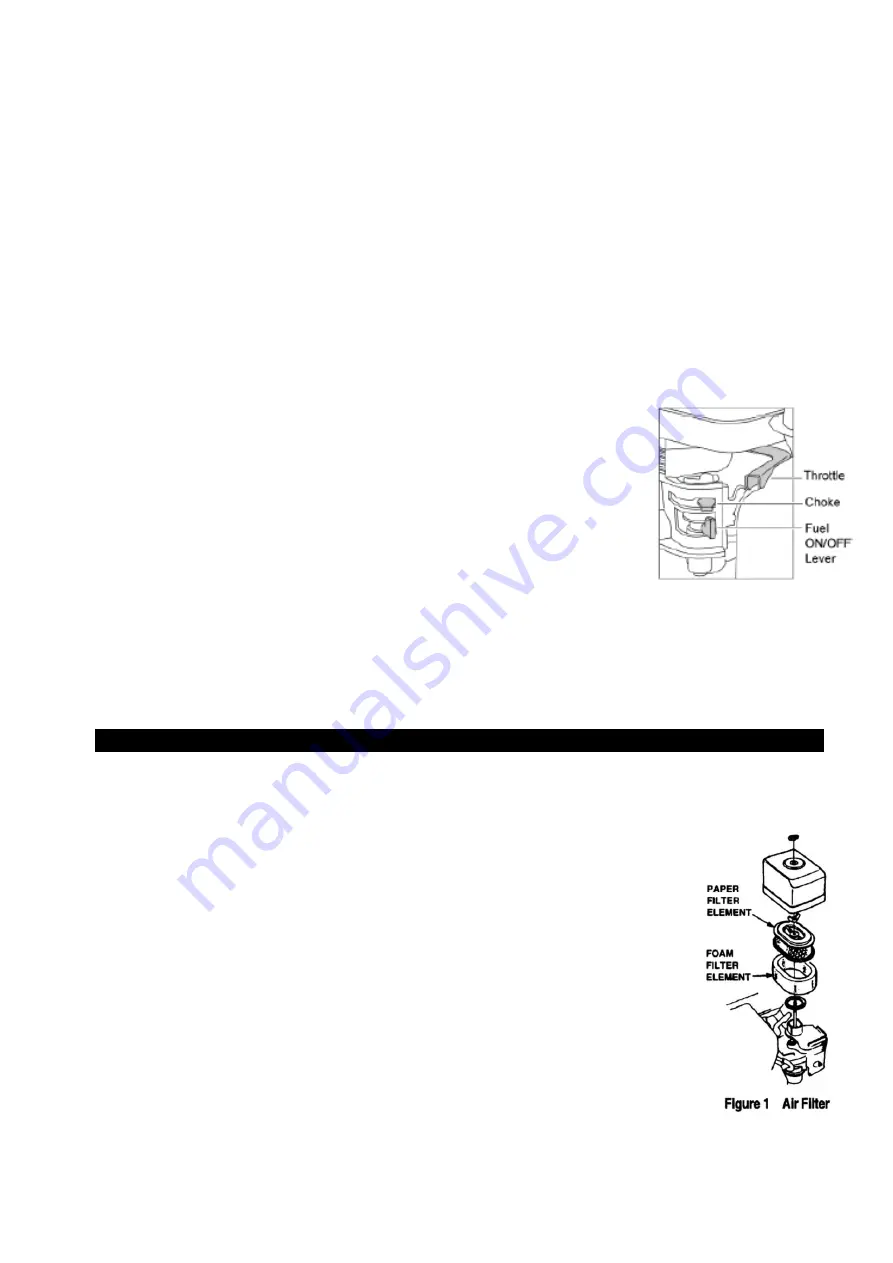

The air filter element should be cleaned because a clogged air cleaner can

cause poor engine starting, lack of power and shorten engine life substantially.

To clean or replace air filter loosen the wing nut on the air filter housing (Figure 1),

remove the cover and take out air filter cartridge. If only cleaning of the air filter

is desired blow through the air filter cartridge from the inside, moving a jet of dry

compressed air up and down until all dust is removed.