BEFORE OPERATION

PUMP SECTION

1. Check that there are no loose screws or components on the machinery.

2. Place the pump on a level surface, but not immediately next to the water supply.

If the pump must be placed on a sloping or inclined surface, a level platform must be used. Be

sure to secure the pump adequately.

3. Where the weight of the suction hose causes the pump to tilt or move, secure the pump adequately.

4. Always attach the strainer to the end of the suction hose. If the pump is operated without the

strainer, pebbles and other materials will be sucked into the pump and could cause damage

and pump failure.

5. Be sure that the strainer is completely submerged, but not in contact with sandy or muddy bot

tom surfaces.

6. Secure the suction and outlet hoses tightly to the pump to avoid sucking air.

FUELING

WARNING!

The following precautions will lessen the risk of fire.

1. Do not smoke near fuel.

2. Mix and pour fuel outdoors and where there are no sparks or flames.

3. Always shut off the engine before refueling. Never remove the fuel tank cap while the engine

is running or right after just stopping the engine.

4. Always open the fuel tank cap slowly to release any

possible overpressure inside the tank.

5. Do not overfill the fuel tank. Stop filling 1 /4-1 /2 inch

from the top of the tan.

6. Tighten the tank fuel cap carefully but firmly after

refilling ..

7. Wipe up any spilled fuel before starting the engine.

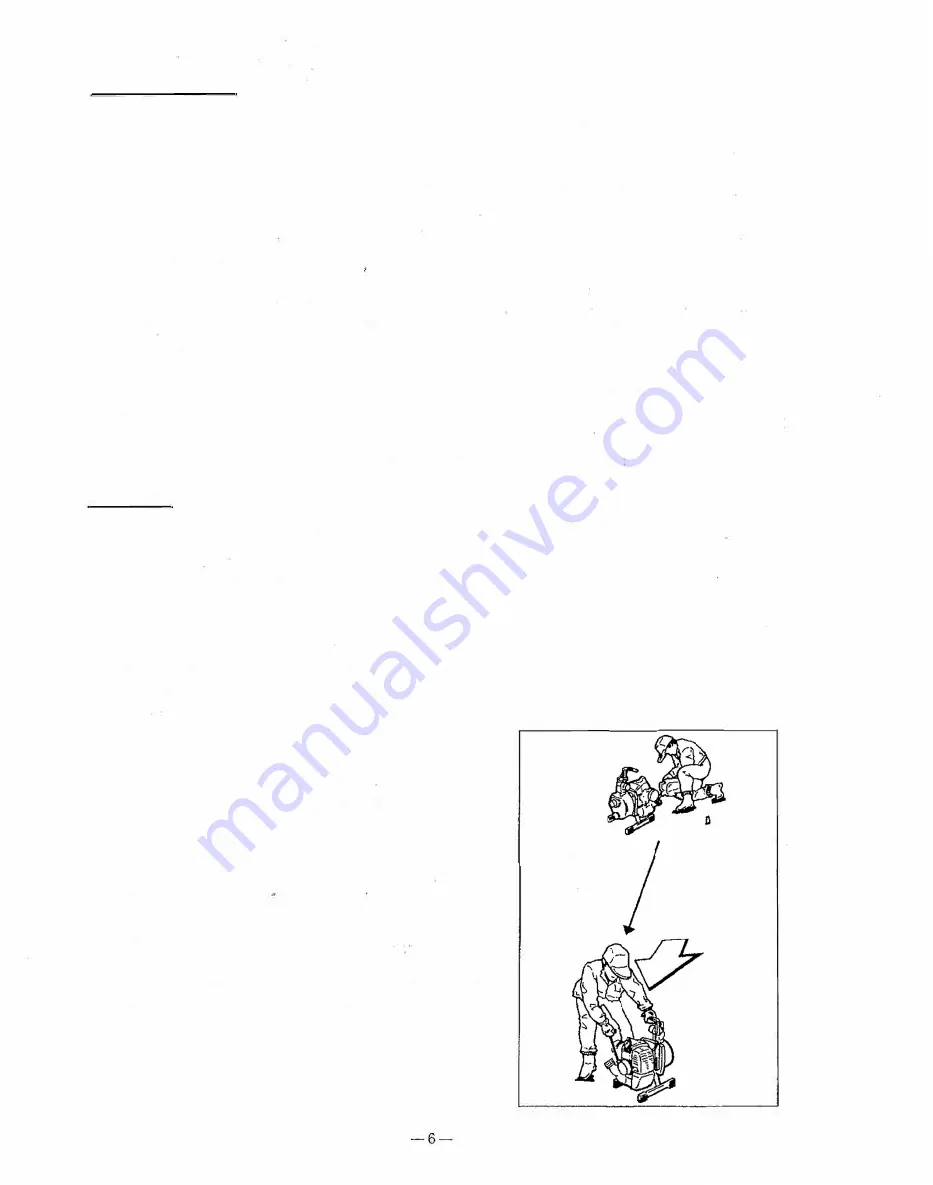

8. Move the water pump at least 1 O feet away from the

fueling location and fuel storage container before

starting the engine.

Min

10 feet

(3m)

D

D

D

D

D