shut off, the folded paper may be removed from the exit ramp and conveyor.

NOTE: The user may find it easier

to run only a few sheets before running an entire stack. This way any adjustments can be made before run-

ning a large quantity of paper.

If hesitation occurs in the paper feeding, review machine set-up as described in

section

2.0

of this manual. Pay particular attention to paper guide placement. If the edges of the folded paper do

not line up, adjust the skew by turning the skew thumbscrew slightly. Retest with a few sheets and adjust as nec-

essary to square up the fold.

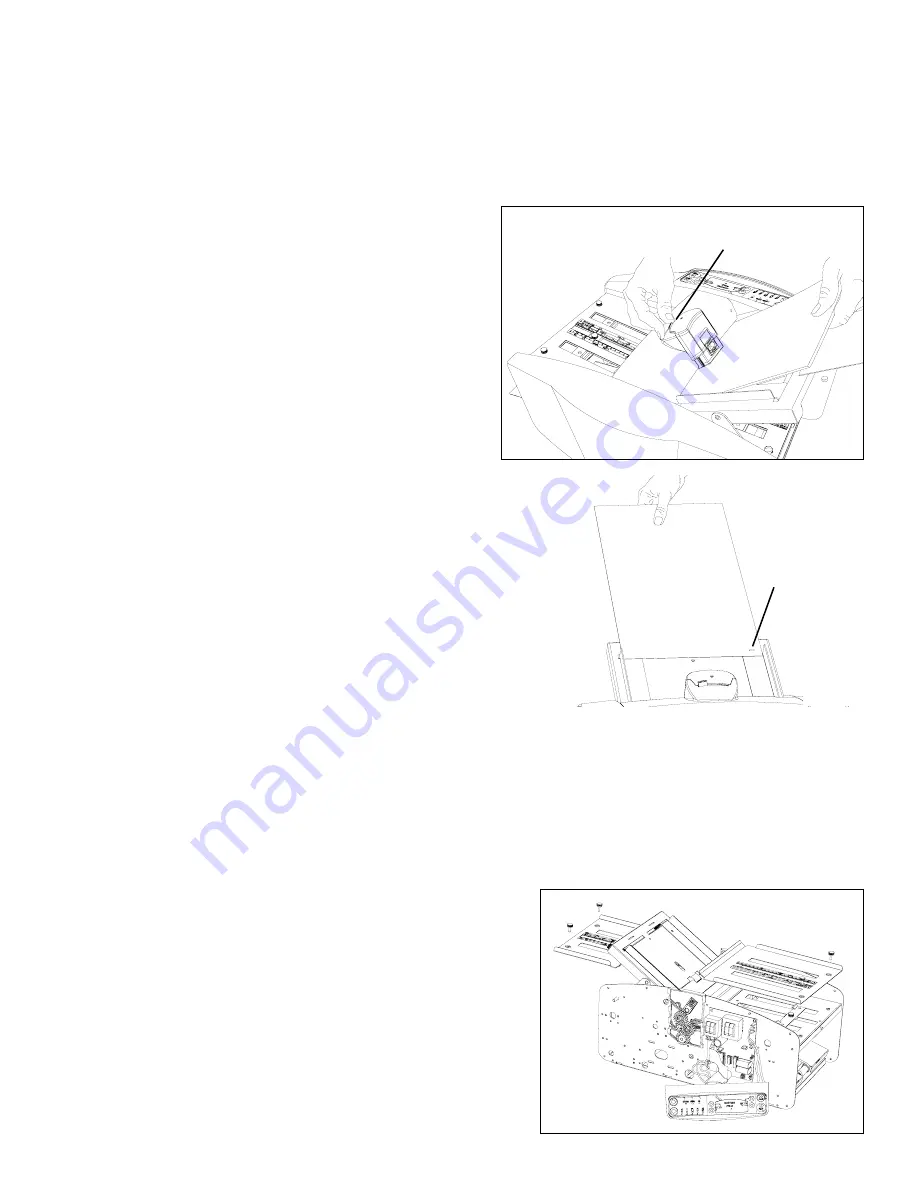

4.2 Manual Feed Operation of Multiple Sets

The Model 1701 is capable of folding single sheets or sets of

sheets up to 5 pages of #20 bond manually (one at a time).

To do so, set up the machine as described earlier in section

2.0

. With one hand, push the manual feed

lever

on the top

cover to raise the entire retarder and paper pusher assembly.

While holding the lever, insert the paper all the way under the

retarder until it stops, using the paper guides to keep it

square

(Fig. 14)

. The lever then can be lowered onto the

paper. Press the

Pulse Key

and hold until the folded paper

exits the conveyor.

4.3 Folding Stapled Sets of Paper

The Model 1701 is capable of folding stapled sets of paper up

to 5 sheets of #20 bond in the manual method described in

section

4.2

. However, a few simple rules must be followed to

prevent jams or roller damage. Always attach the staple par-

allel to the fold rollers. Always feed the stapled set in with the

stapled edge first

(Fig. 15)

. Avoid using loose fitting staples

or inserting them too close to the edge (less than 5/16",

8mm).

5.0 Maintenance

5.1 Fold Roller Removal and Cleaning

During normal operation, the fold rollers will become con-

taminated with paper dust, ink, copy toner and other per-

formance-inhibiting materials. At some point this will cause problems such as wrinkling or marking the paper and

even miss-folds or paper jams. At this time, cleaning the rollers will be necessary. Follow these steps to remove

the roller assembly:

1. Before turning the power off, use the custom fold button (

key C

) to move the 2nd fold paper stop out to its

longest position.

2. Turn off the power and disconnect the power cord from the outlet.

3. Remove (6) Philips pan head screws from each of the side covers. Remove the side covers by leaning them

out at the top and sliding outward at the bottom. Be careful with the electronic control display and switch wires

on the right cover.

4. Remove the drive belt by loosening

(do not remove)

the four

nuts on the motor and sliding the motor to the left. Slip the

belt off the top edge of the large pulley, then the motor pul-

ley. Do not over tighten the belt tension during re-installation.

5. Remove the four thumbscrews securing the 1st and 2nd

upper fold tables. Pull the upper fold tables straight out a

few inches to disengage the bearing blocks. The upper

tables can then be lifted out of the way

(Fig. 16)

.

6. Lower the feed table by pulling the feed table legs away

from the folder and letting the feed table down.

7. Remove the top cover assembly via the four Philips flat

head screws. Be careful not to damage the exposed paper

pusher spring or retarder during handling.

Fig. 15

Always feed the

stapled set in

with the stapled

edge first and

parallel to the

fold rollers

Fig. 14

Push spring loaded

lever

away

from operator

and insert paper into the folding rollers

Fig. 16

(6)