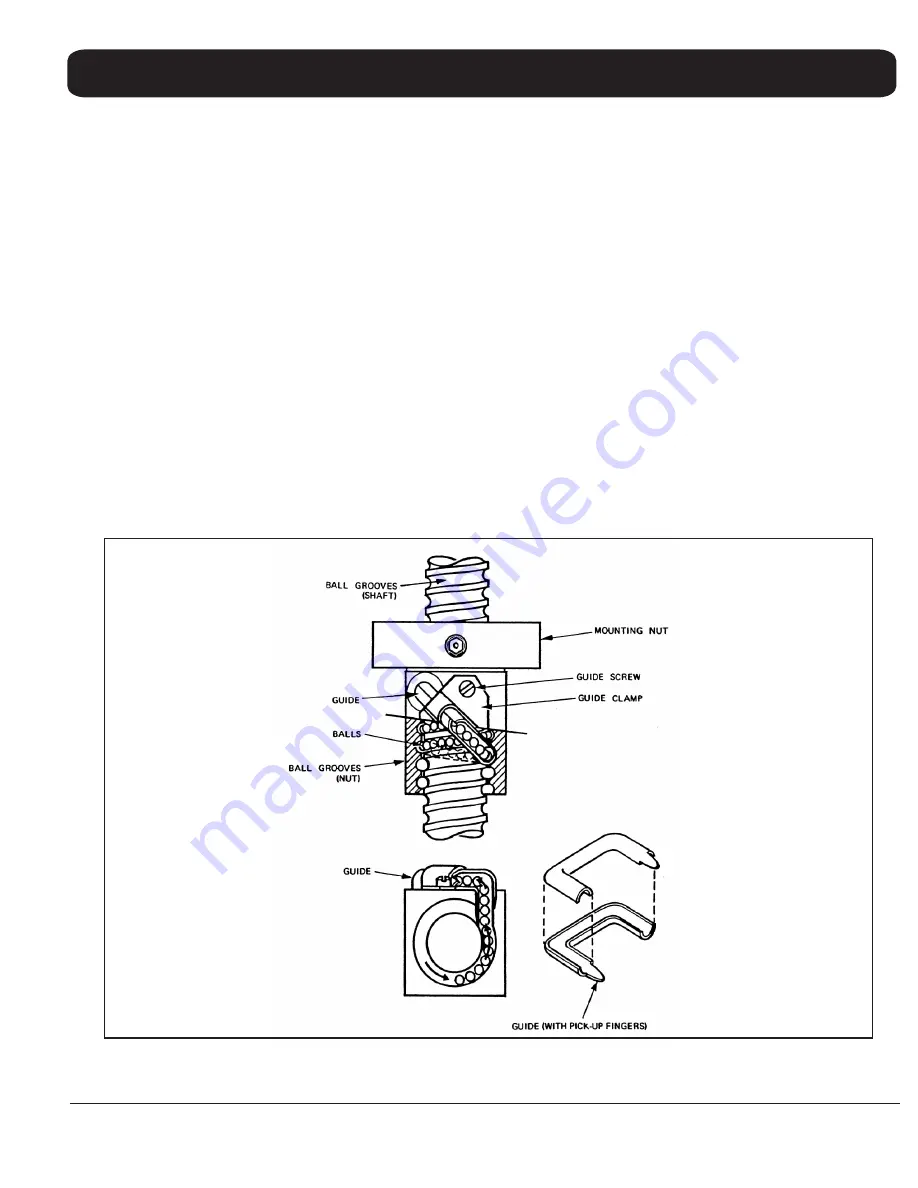

Figure 3-2

Ball Nut Assembly

3-3

Form No. S-2110 08/03

Printed in U.S.A

.

SECTION 3 maintenance

1. Remove the two bolts (8) which hold the ball nut

assembly in the screw lever (7).

2. Remove the two 5/16" hex head cap screws (13)

which fasten the screw housing (14) to the cabinet frame

(not shown).

3. Lift screw assembly from the cabinet.

Proceed in reverse order to replace the assembly.

3.3.5.2 General Inspection and Cleaning:

The screw

assembly should run smoothly throughout the entire

stroke. If operation is not uniform remove the screw

assembly (paragraph 3.3.5.1) and proceed as follows:

1. Inspect screw shaft for signs of accumulation of foreign

matter in the ball grooves.

2. Using cleaning fluid or solvent remove dirt from ball

grooves. Be sure to flush the ball nut assembly

thoroughly.

3. Cycle the ball nut along the screw shaft several times.

Wipe with a dry lintless cloth and lubricate

immediately. (See lubrication 3.2.2).

4. If assembly continues to operate erratically after

cleaning disassemble and inspect the ball nut

assembly.

3.3.5.3 Ball Nut Disassembly:

The Saginaw Screw is a

ball bearing screw power transmission device which

converts the turning motion applied by the hand crank (

1) into bi-directional force against the screw lever (7).

The frictionless "easy" transfer results from the use of

bearing balls circulated be- tween the screw and nut in

concave helical grooves. As the screw rotates inside the

nut, the bearing balls are directed from one end and

carried by a ball guide to the opposite end of the ball nut.

Figure 3-2 shows a cut-away view of the ball nut.