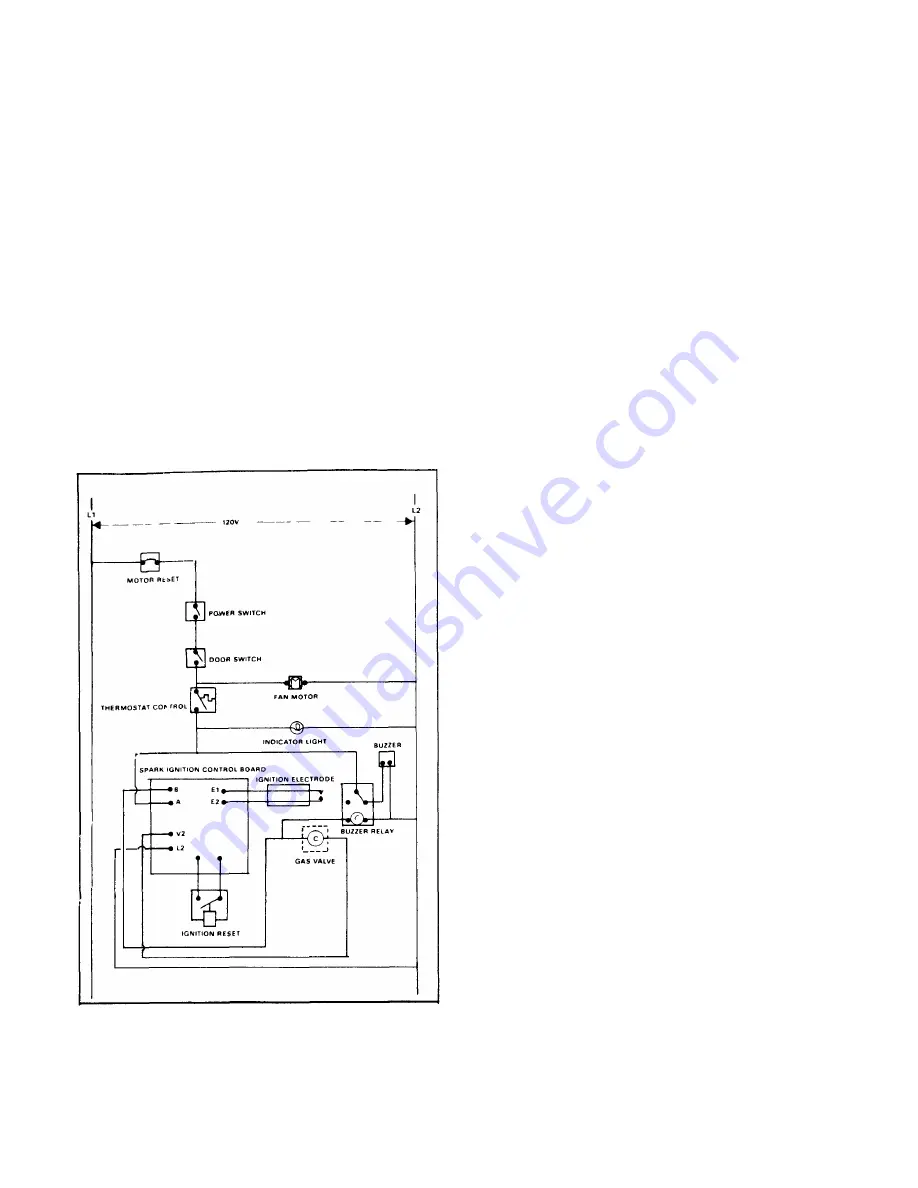

4.3 ELECTRICAL CIRCUITS

120 volt a-c power is supplied to the fan motor,

indicator light, and ignition control board, which in turn

controls power to the burner electrodes. IGNITION RESET

switch, and gas valve solenoid Input power is connected at

the junction box mounted (behind an access cover) at the

lower right rear of the oven.

4.3.1 Control Circuit Components

The control circuit is shown in the simplified schematic

drawing Figure 4-2. A brief description of major electrical

control circuit components is included in the following

paragraphs.

4.3.1.1 Door Interlock Switch

The interlock switch is a single pole, two-position

micro-switch with normally open contacts. The switch lever

is operated by an actuating

Figure 4-2 Simplified Schematic — Controls in OFF position

bar built into the door jamb of the right side door When the

door is open, the bar remains retracted with the switch

contacts in the norm ally open position. When the door is

closed, the door pushes the actuating bar against the switch

lever to close the contacts. Connected into the circuit for the

fan and ignition system, the door switch interrupts fan

operation and deactivates the ignition system when the door

is opened

4.3.1.2 Thermostat Control

The thermostat is a bulb and capillary type system,

manually adjustable from 200-475°F

(94-246°C)

.The oven is

put into an automatic heating cycle with the setting of the

thermostat to any of its calibrated temperature settings.

Expansion and contraction of gas with in the cap-

illary/bellows s ystem in response to temperature change

opens and closes the thermostat contacts, energizing and

de-energizing the ignition control system

4.3.1.3 Direct Spark Ignition System

The direct spark ignition system consists of the

electrodes, ignition control board, and as sociated wiring. On

a call for heat, input power is applied to the control board.

Sparking is then initiated and the gas valve is energized.

Sparking continues with the gas valve powered for a "trial

for ignition" period of 3.3 seconds. If flame has not been

established by the end of the trial period, the system will

lock out, the gas valve will close, the reset function will trip

out, and a warning buzzer will sound. Reset action is man-

ually accomplished by pressing IGNITION RESET switch In

normal operation, as soon as flame is established and

proven by the flame sensing circuitry, sparking will cease

immediately and the system will remain "on", monitoring the

flame until the end of the duty cycle. Should flame-out occur

during the duty cycle, the sys tem will reactivate the spark to

provide for reignition.

The flame will either be reestablished or the system will

lock out in the normal manner. Should lock-out occur, the

system is reactivated by the IGNITION RESET switch

located on the control panel.

4-2

Summary of Contents for 2500 HE

Page 7: ...Figure 2 2 28 711mmi Open Stand Inverted for Assembly Figure 2 3 Stacked Ovens ...

Page 13: ...HIGH EFFICIENCY CONVECTION OVEN 3 2 ...

Page 26: ...MAINTENANCE Figure 6 3 Air Shutter Adjustment 6 5 ...

Page 28: ...Figure 7 1 Frame and Cabinet Assembly ...

Page 30: ...HIGH EFFICIENCY CONVECTION OVEN Figure 7 2 Gas Burner and Manifold Assembly 7 4 ...

Page 32: ...7 6 HIGH EFFICIENCY CONVECTION OVEN Figure 7 3 Door Assembly ...

Page 34: ...HIGH EFFICIENCY CONVECTION OVEN 7 8 Figure 7 4 Control Panel Assembly ...

Page 36: ...7 10 HIGH EFFICIENCY CONVECTION OVEN Figure 7 5 Ignition Control Board Assembly ...