20

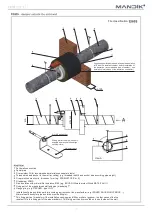

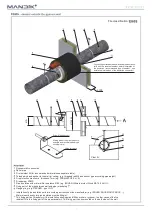

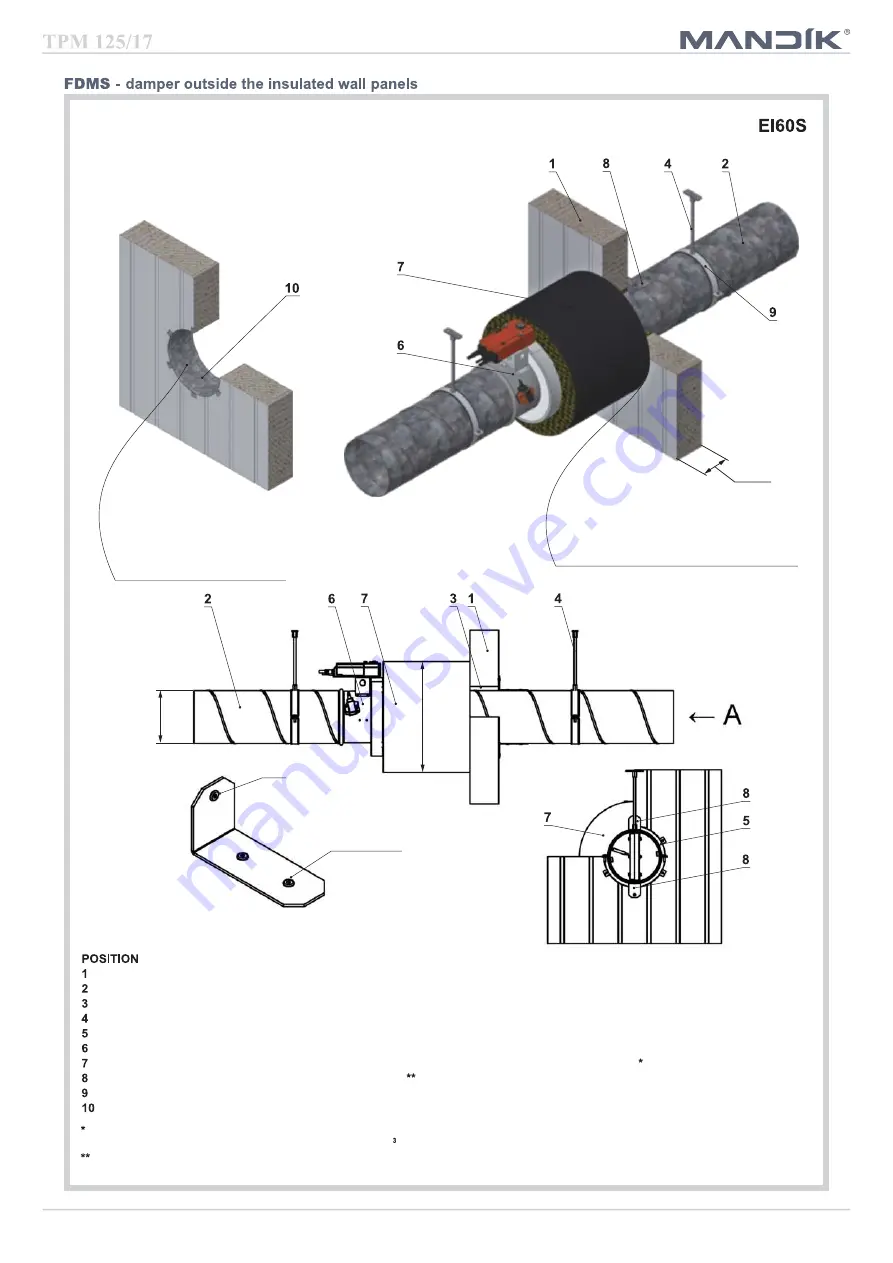

Installation of pipe insulation perform according instructions of the manufacturer (e.g. ISOVER, ROCKWOOL,PAROC ...).

Minimal wool density for pipe insulation must be 66kg/m.

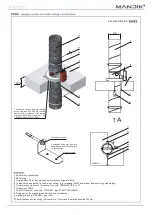

This fixing part isn't mandatory if the installation opening was fulfill by mortar or gypsum. In other cases of the fire

resistant fill is this fixing part of the pipe mandatory. This fixing part can by mounted on the both sides of the wall.

Insulated wall construction (e.g. KINGSPAN - type KS1150 FR)

Spiral pipe

Fire resistant fill (for recommended materials see separate table)

Threaded rod and anchor to the wall (or ceiling) (e.g. threaded rod M8 and anchor type according pipe weight)

Fire protection mastic min. thickness 1mm (e.g. PROMASTOP-P or K)

Fire damper FDMS

Pipe insulation with minimal fire resistance EI60 (e.g. ISOVER Ultimate protect Wired MAT 4.0 ALU1)

Fixing part of the pipe between wall and pipe (mandatory)

Hanging ring (e.g. FISCHER - type LGS)

Installation ring

Before instalation of the fire resistant

stopper inside the instalation opening

put special connection ring. This ring

cover insulation inside the panel and

connect outside and inside plane of

the panel.

Connecting surface between wall and pipe insulation

fulfil with fire resistant sealant before instalation of

the insulation (recommended type of sealant - see

instalation instructions of the insulation contractor).

Fire classification:

≥

100

View A:

Ø

D

Ø

D

+2

00

Rivet

8-fixing part of the pipe (see only

example and recommneded type

on this picture)

Holes for rivets

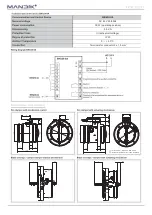

Summary of Contents for FDMS Series

Page 1: ......

Page 12: ...11 Fire classification 96 47 47 96 96...

Page 15: ...14 Fire classification 96 47 47 96 96...

Page 18: ...17 Fire classification 96 47 47 96 96...

Page 29: ...28...

Page 30: ...29...

Page 31: ...30...