24

TPM 083/12

11. Material

IV. MATERIAL, FINISHING

V. INSPECTION, TESTING

12. Inspection, testing

13. Logistic terms

VI. TRANSPORTATION AND STORAGE

VII. ASSEMBLY, ATTENDANCE, MAINTENANCE AND REVISIONS

14. Assembly

15. Entry into service and revisions

11.1.

Damper bodies are supplied in the design made of galvanized plate without any other surface

finishing.

Damper blades are made of fire resistant asbestos free boards made of mineral fibres.

Damper controls are made of galvanized materials with no other surface finish.

Fasteners is galvanized. Fasteners is galvanized.

11.2.

According to the customer's requirements, damper body, control, springs and jointing material

can be made of stainless material.

12.1.

The appliance is constructed and preset by the manufacturer, its operation is dependent on

proper installation and adjustment.

13.1.

Dampers are transported by box freight vehicles without direct weather impact, there must not

occur any sharp shocks and ambient temperature must not 40 °C. Dampers must be

protected against mechanic damages when transported and manipulated. During transportation,

the damper blade must be in the "CLOSED" position.

13.2.

Dampers are stored indoor in environment without any aggressive vapours, gases or dust. Indoor

temperature must be in the range from -5 °C to +40 °C and maximum relative humidity 80 %.

Dampers must be protected against mechanic damages when transported and manipulated.

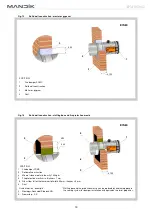

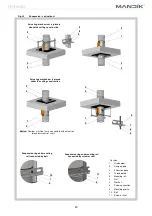

14.1.

All effective safety standards and directives must be observed during fire damper assembly.

14.2.

To ensure reliable fire damper function it is necessary to avoid blocking the closing mechanism

and contact surfaces with collected dust, fibre and sticky materials and solvents.

15.1.

Before entering the dampers into operation after their assembly and by sequential checks, the

following checks must be carried out.

Visual inspection of proper damper integration, inside damper area, damper blade, contact

surfaces and silicon sealing.

Inspection hole disassembly: release the covering lid by removing the two screws in the corners

of inspection hole. Then remove lid from its original position.

Summary of Contents for FDMC

Page 1: ......