5

Weights and effective area

0,3

0,0027

15,5

0,4

0,0056

28

0,55

0,0115

45,5

0,75

0,0206

72,5

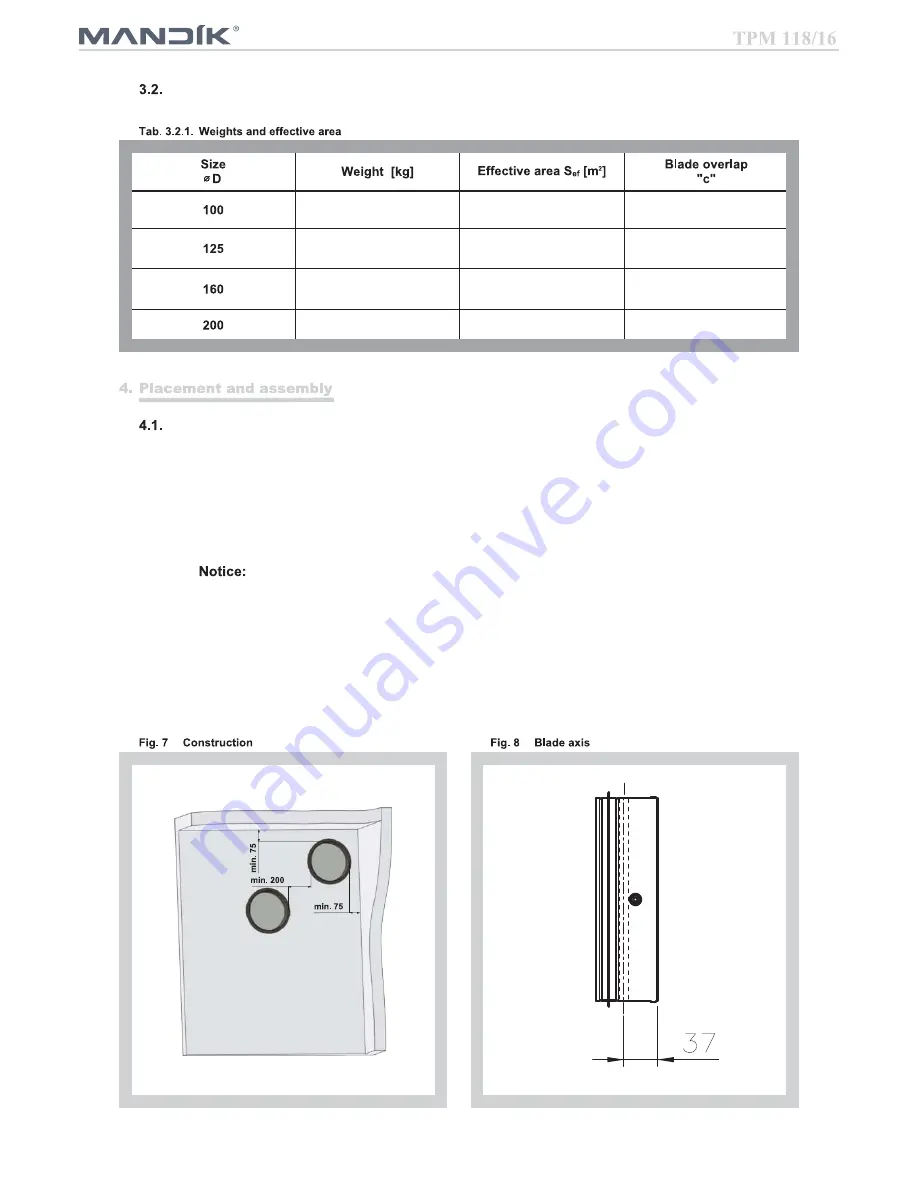

Fire dampers are suitable for installation in arbitrary position in vertical and horizontal passages

of fire separating constructions. Duct assembly procedures must be done so as all load transfer

from the fire separating constructions to the duct in the placement of fire damper installation is

absolutely excluded. Installation gap must be filled by approved material perfectly in all the

installation space volume (installation gap).

To provide needed access space to the control device, all other objects must be situated at least

350 mm from the control parts of the damper. Inspection hole must be accessible.

Damper has to be accessible for regular checks and maintenance.

Fire damper is inserted inside the duct. Blade has to be inside of fire separating

construction (after closing).

The distance between the fire damper and the construction (wall, ceiling) must be at least 75 mm.

In case that two or more dampers are supposed to be installed in one fire separating construction,

the distance between the adjacent dampers must be at least 200 mm according to EN 1366-2

paragraph 13.5.