1

2

3

4

Removing and Installing Oil Spray Nozzle

65

Removing oil spray nozzle

D

Draining off oil, see page 60

D

Removing the oil pan, see page 60

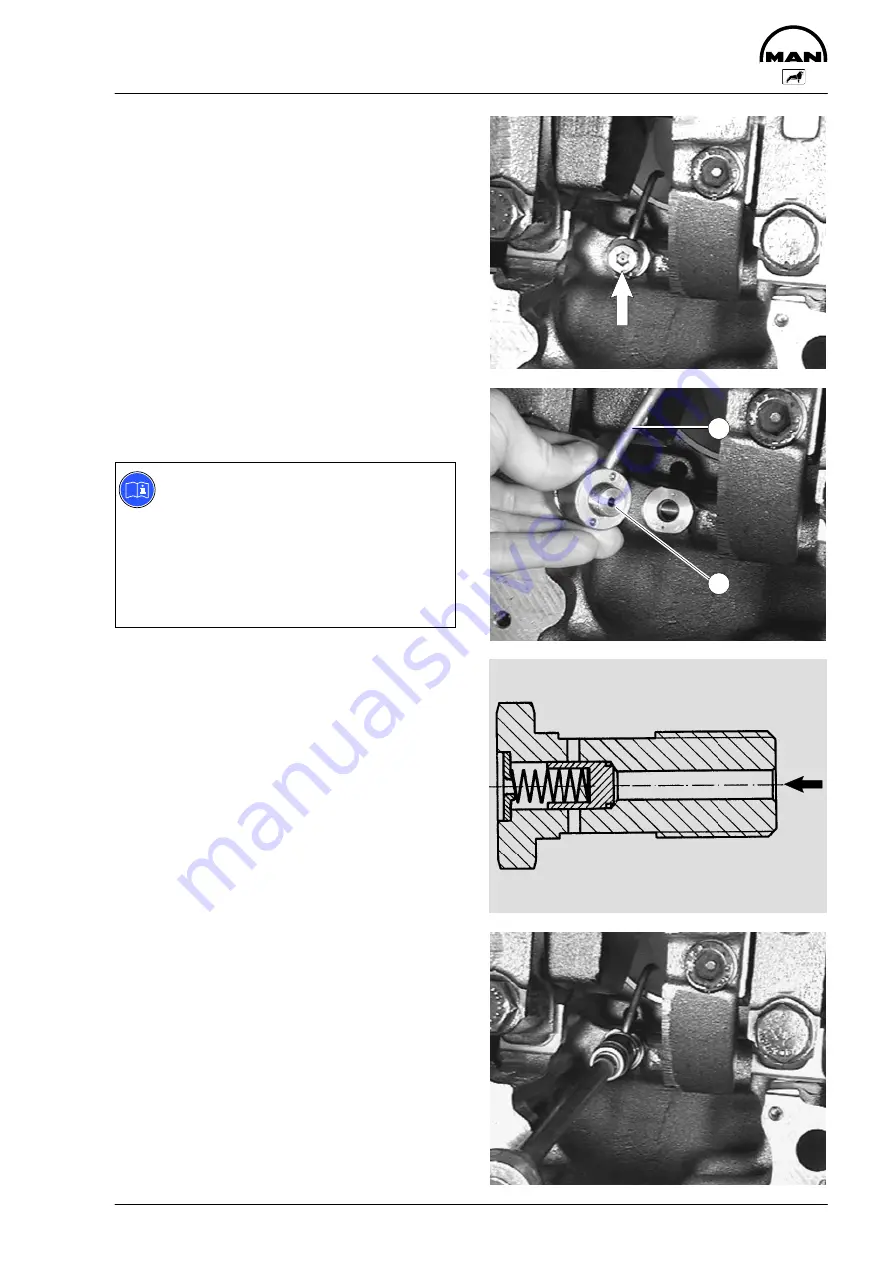

Fig. 1

Unscrew the oil spray nozzle valve (arrowed) and

remove with the oil spray nozzle.

Fig. 2

1 Oil spray nozzle valve

2 Oil spray nozzle

Note:

The oil spray nozzles are provided with

balls. When the oil spray nozzle valve is

tightened at the factory, the balls are

pressed into the crankcase where they

make impressions which are used as

marker points for installing the nozzle in

the event of repairs.

Checking oil spray nozzle valve

Fig. 3

Use a piece of wire to check whether the valve

plunger is easy to move.

Opening pressure, see “Service Data”.

Installing the oil spray nozzle

Fig. 4

Screw in the oil spray nozzle together with its

valve.

The balls of the oil spray nozzle must be located in

the impressions designated for this purpose in the

crankcase. This ensures that the nozzle is secured

in the correct installation position.

Turn the engine. The crankshaft drive or pistons

must not collide with the oil injection nozzle.

Tighten the securing bolts with the prescribed tor-

que.

2

1

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......