18

6. Troubleshooting

Review the troubleshooting procedures in this section if a problem develops with your machine. If you

need replacement parts or additional help with a procedure, please contact with us.

Note: Please gather the serial number and manufacture date of your machine before calling.

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Machine does not

start, or power supply

fuse/breaker trips

immediately after

startup.

1. Cyclone dust collector not properly

connected to ducting.

2. Incorrect power supply voltage or circuit

size.

3. Power supply circuit breaker tripped or

fuse blown.

4. Motor overheated.

5. Wiring open/has high resistance.

6. Power switch at fault.

7. Capacitor at fault.

8. Motor at fault.

1. Connect dust collector to ducting.

2. Ensure correct power supply voltage and circuit

size.

3. Ensure circuit is sized correctly and free of shorts.

Reset circuit breaker or replace fuse.

4. Allow motor to cool, reset overload if necessary.

5. Check/fix broken, disconnected, or corroded

wires.

6. Test/replace.

7. Replace.

8. Test/repair/replace.

Machine seems

underpowered.

1. Motor overheated.

2. Dust-collection ducting problem.

3. Canister filter clogged/at fault.

4. Dust collector too far from machine or

undersized for dust-collection system.

5. Capacitor at fault.

6. Motor bearings at fault.

1. Allow motor to cool, reset overload if necessary.

2. Clear blockages, seal leaks, use smooth-wall

duct, eliminate bends, close other branches.

3. Clean canister filter; replace canister filter.

4. Move closer to machine/redesign ducting layout/

upgrade dust collector.

5. Test/repair/replace.

6. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

Machine has vibration

or noisy operation.

1. Motor or component loose.

2. Motor fan rubbing on fan cover.

3. Motor mount loose/broken.

4. Impeller damaged, unbalanced, or loose.

5. Motor bearings at fault.

6. Motor shaft bent.

1. Inspect/replace damaged bolts/nuts, and

retighten with thread-locking fluid.

2. Fix /replace fan cover; replace loose/damaged

fan.

3. Tighten/replace.

4. Inspect/tighten/replace.

5. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

6. Test with dial indicator. Replace motor if

damaged.

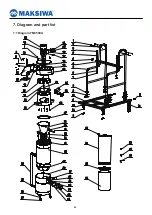

2

Greetings,

Congratulations, you just purchased the BMS.3200.IR Precision Saw, which was developed with the

Maksiwa’s highest standards of technology and quality. Your BMS.3200.IR Precision Saw allows you

to have the highest productivity in woodworking. Besides a great finish, the BMS.3200.IR ensures that

your cuts are always precise. It should be noted that to use this machine with maximum efficiency,

you should read and understand the instructions in this manual.

Visit our website to know about our launches and other product lines:

www.maksiwa.com