16 ENGLISH

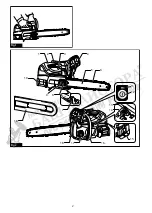

1.

Press the lock-off lever, then pull the switch trig

-

ger. The saw chain starts immediately.

2.

Push the front hand guard forwards with the back

of your hand. Make sure that the chain saw comes to an

immediate standstill.

►

Fig.7:

1.

Front hand guard

2.

Unlocked position

3.

Locked position

Checking the run-down brake

CAUTION:

If the saw chain does not stop

within two seconds in this test, stop using the

chain saw and consult our authorized service

center.

Run the chain saw then release the switch trigger com-

pletely. The saw chain must come to a standstill within

two seconds.

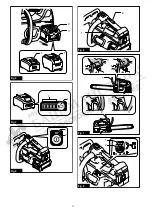

Adjusting the chain lubrication

You can adjust the oil pump feed rate with the adjusting

screw using the universal wrench. The amount of oil

can be adjusted in 3 steps. Open the cap to adjust the

adjusting screw.

►

Fig.8:

1.

Cap

2.

Adjusting screw

Carabiner (rope attachment point)

You can hang the tool by attaching the rope to the cara-

biner. Pull up the carabiner, and then tie it with the rope.

►

Fig.9:

1.

Carabiner

Spike bumper

The tool is equipped with the spike bumper as stan-

dard. For replacement of the spike bumper, ask Makita

Authorized Service Centers.

When you perform the cutting operation, engage the

spike bumper with the trunk and use it as a lever.

Electronic function

The tool is equipped with the electronic functions for

easy operation.

•

Electric brake

This tool is equipped with an electric brake. If

the tool consistently fails to quickly stop after the

switch trigger is released, have the tool serviced at

a Makita service center.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

CAUTION:

Do not touch the saw chain with

bare hands. Always wear gloves when handling

the saw chain.

Installing or removing saw chain

CAUTION:

The saw chain and the guide bar

are still hot just after the operation. Let them cool

down enough before carrying out any work on

the tool.

CAUTION:

Carry out the procedure of install-

ing or removing saw chain in a clean place free

from sawdust and the like.

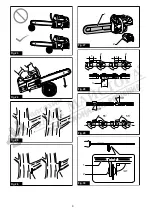

Installing the saw chain

To install the saw chain, perform the following steps:

1.

Release the chain brake by pulling the front hand

guard.

2.

Loosen the chain adjusting screw, then the retain

-

ing nut.

►

Fig.10:

1.

Sprocket cover

2.

Chain adjusting screw

3.

Retaining nut

3.

Remove the sprocket cover.

4.

Check the direction of the saw chain. Match the

direction of the saw chain with that of the mark on the

chain saw body.

►

Fig.11:

1.

Mark on chain saw body

5.

Fit one end of the saw chain on the top of the

guide bar.

6.

Fit the other end of the saw chain around the

sprocket, then attach the guide bar to the chain saw

body, aligning the hole on the guide bar with the pin on

the chain saw body.

►

Fig.12:

1.

Sprocket

2.

Hole

7.

Insert the protrusion and the pin on the sprocket

cover to the chain saw body, and then close the cover

so that the bolt and pin on the chain saw body meet

their counterparts on the cover.

►

Fig.13:

1.

Protrusion

2.

Sprocket cover

3.

Bolt

4.

Pin

8.

Tighten the retaining nut to secure the sprocket

cover, then loosen it a bit for tension adjustment.

►

Fig.14:

1.

Retaining nut

After installing the saw chain, adjust the saw chain

tension by referring to the section for adjusting saw

chain tension.

Removing the saw chain

To remove the saw chain, perform the following steps:

1.

Release the chain brake by pulling the front hand

guard.

2.

Loosen the chain adjusting screw, then the retain

-

ing nut.

►

Fig.15:

1.

Chain adjusting screw

2.

Retaining nut

3.

Remove the sprocket cover then remove the saw

chain and guide bar from the chain saw body.

Summary of Contents for UG002G

Page 2: ...2 Fig 1 3 1 2 5 6 11 12 14 7 8 9 10 16 17 19 15 13 4 18 Fig 2 ...

Page 3: ...3 1 1 2 3 Fig 3 1 2 Fig 4 1 2 Fig 5 2 1 Fig 6 3 2 1 2 3 Fig 7 2 1 Fig 8 ...

Page 4: ...4 1 Fig 9 2 3 1 Fig 10 1 Fig 11 2 1 Fig 12 1 4 2 3 4 Fig 13 1 Fig 14 1 2 Fig 15 1 Fig 16 ...

Page 5: ...5 3 2 1 Fig 17 1 Fig 18 1 2 Fig 19 1 2 3 Fig 20 1 2 Fig 21 Fig 22 ...

Page 6: ...6 Fig 23 Fig 24 1 2 Fig 25 Fig 26 2 1 Fig 27 2 2 1 1 3 1 Fig 28 30 30 55 55 Fig 29 1 2 Fig 30 ...

Page 7: ...7 30 1 5 1 Fig 31 Fig 32 Fig 33 Fig 34 1 2 Fig 35 1 2 Fig 36 1 2 Fig 37 ...