R

epair

P 11 / 22

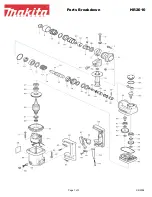

< 10 > Disassembling tool holder guide section

( 1 ) After removing change lever ( See page 9), separate gear housing from motor housing as illustrated

in Fig. 40 and Fig. 41 in page 10.

( 1 ) Apply grease to spur gear 51 and tool holder guide referring to "< 2 > Lubrication to the machine parts"

in page 3.

( 2 ) Mount spur gear 51, compression spring 32 and washer 31. See Fig. 48.

( 3 ) Pressing the washer 31 toward the spur gear 51 side, with arbor press, mount ring spring 29 as illustrated

in Fig. 47 and Fig. 46. And mount flat washer 28 to the position illustrated in Fig. 45.

( 4 ) Insert piston cylinder of swash bearing section into tool holder guide. And insert tool holder section into inner

housing as illustrated in Fig. 45.

( 2 ) Remove inner housing as illustrated in Fig. 44.

( 3 ) Separate tool holder guide section from inner housing. See Fig. 45.

( 4 ) Remove ring spring 29, while pressing washer 31 which covers ring spring 29, toward the spur gear 51 side.

See Fig. 46 and 47. After removing ring spring 29, reduce pressure on the washer 31 slowly.

( 5 ) Remove washer 31, compression spring 32 and spur gear 51 form tool holder guide. See Fig. 48.

< 11 > Assembling tool holder guide section

Fig. 44

Fig. 45

Fig. 46

Fig. 47

Fig. 48

Washer 31

Ring

spring 29

Round bars

for arbor

Retaining ring

plier

No. 1R306

Ring spring

extractor

Tool holder

guide section

Tool holder

guide section

Swash bearing

section

Swash bearing

section

Piston cylinder

Inner

housing

Flat washer 28

Washer 31

Ring

spring 29

Retaining

ring plier

Washer 31

Spur gear 51

Tool

holder guide

Compression

spring 32

Inner housing