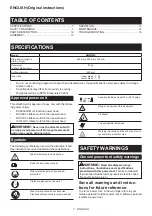

14 ENGLISH

MAINTENANCE

WARNING:

Before inspecting or maintaining

the equipment, switch off the motor and remove

the spark plug cap or battery cartridge.

Otherwise

the cutting tool or other parts may move and result in

serious injury.

WARNING:

When inspecting or maintaining

the equipment, always put it down.

Assembling or

adjusting the equipment in an upright position may

result in serious injury.

WARNING:

Follow the warnings and precau-

tions in the section for safety warnings and the

instruction manual of the power unit.

NOTICE:

Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

Overall inspection

•

Tighten loose bolts, nuts and screws.

•

Check for damaged parts and blades. Ask our

authorized service center to replace them if

necessary.

Cleaning the tool

Clean the attachment by wiping off dust, dirt, or cut off

grass with a dry cloth or one dipped in soapy water and

wrung out. Remove the cut off grass or debris adhered

to the cutter blade.

Dismounting the cutter blades

CAUTION:

Always wear gloves when dis-

mounting the cutter blades.

When cleaning, sharpening, or replacing the cutter

blades, dismount them by the following procedure:

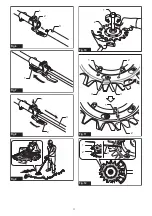

1.

Remove the blade cover.

2.

Set the box wrench onto the nut. Rotate the box

wrench so that the hole in the lower blade aligns with

the hole in the upper blade.

►

Fig.10:

1.

Box wrench

2.

Hole in the lower blade

Look into the hole in the lower blade to check if the

correct hole in the upper blade is aligned. In the upper

blade, there are pins and two types of holes; true circle

and oval. Align the true circle hole in the upper blade

with the hole in the lower blade and then insert the hex

wrench into the holes.

►

Fig.11:

1.

Hole in the lower blade

2.

True circle hole

in the upper blade

3.

Oval hole in the upper

blade

4.

Pin

►

Fig.12:

1.

Lower blade

2.

Upper blade

3.

Hex

wrench

NOTE:

Choose the true circle hole in the upper blade

by referring the following information:

•

When you rotate the lower blade counterclock

-

wise, the true circle hole comes after the pin.

•

When the oval hole is aligned with the hole in

the lower blade, you can insert the hex wrench

but there is a lot of backlash.

•

When the pin is aligned with the hole in the

lower blade, you can see the screw thread in

the pin. In this case, you cannot insert the hex

wrench fully.

CAUTION:

Do not put your fingers on the

blade when rotating the box wrench.

The blades

rotate as you rotate the box wrench and it may cause

personal injury.

CAUTION:

Always use the box wrench when

aligning the holes in the upper and lower blades.

3.

While inserting the hex wrench, turn the bolt clock-

wise using the box wrench to loosen the bolt.

►

Fig.13:

1.

Box wrench

2.

Hex wrench

4.

Remove the bolt, clamp washer, and the holder

together with the lower blade.

►

Fig.14:

1.

Bolt

2.

Clamp washer

3.

Holder (for lower

blade)

4.

Lower blade

5.

While pushing the upper blade, rotate it counter-

clockwise to position the pin as shown in the figure.

After that, lift the upper blade from the holder to remove.

►

Fig.15:

1.

Upper blade

2.

Holder (for upper blade)

3.

Pin

6.

Remove the lower blade. To remove, rotate the

lower blade counterclockwise to position the pin as

shown in the figure and then lift the lower blade from the

holder.

►

Fig.16:

1.

Lower blade

2.

Holder (for lower blade)

3.

Pin

NOTICE:

After dismounting the cutter blades,

keep the bolt, clamp washer, and the holder in

place to avoid them from being lost.

NOTE:

To install the cutter blades, refer to the section

for replacing the cutter blades.

Removing jammed weeds

NOTICE:

Periodically remove jammed weeds

and foreign objects between the cutter blades and

in the holders.

Using this attachment with weeds

jammed inside may result in malfunction.

Dismount the cutter blades. Remove jammed weeds

between the upper and lower blades. Also remove

the jammed weeds in the holders, especially around

the pins, using a brush. Be sure to clean the weeds

adhered to the holder as shown in the figure.

►

Fig.17:

1.

Holder (for upper blade)

2.

Holder (for

lower blade)

Clean the cutter blades with water and dry them com

-

pletely. After that, apply anti-rust oil.