13

Horizontal vise (optional accessory)

1

2

3

4

011305

The horizontal vise can be installed on the left side of the

base. By turning the vise knob counterclockwise, the

screw is released and the vise shaft can be moved

rapidly in and out. By turning the vise knob clockwise, the

screw remains secured. To grip the workpiece, turn the

vise knob gently clockwise until the projection reaches its

topmost position, then fasten securely. If the vise knob is

forced in or pulled out while being turned clockwise, the

projection may stop at an angle. In this case, turn the vise

knob back counterclockwise until the screw is released,

before turning again gently clockwise.

The maximum width of the workpiece which can be

secured by the horizontal vise is 120 mm.

WARNING:

•

Grip the workpiece only when the projection is

at the topmost position.

Failure to do so may

result in insufficient securing of the workpiece. This

could cause the workpiece to be thrown, cause

damage to the blade or cause the loss of control,

which can result in PERSONAL INJURY.

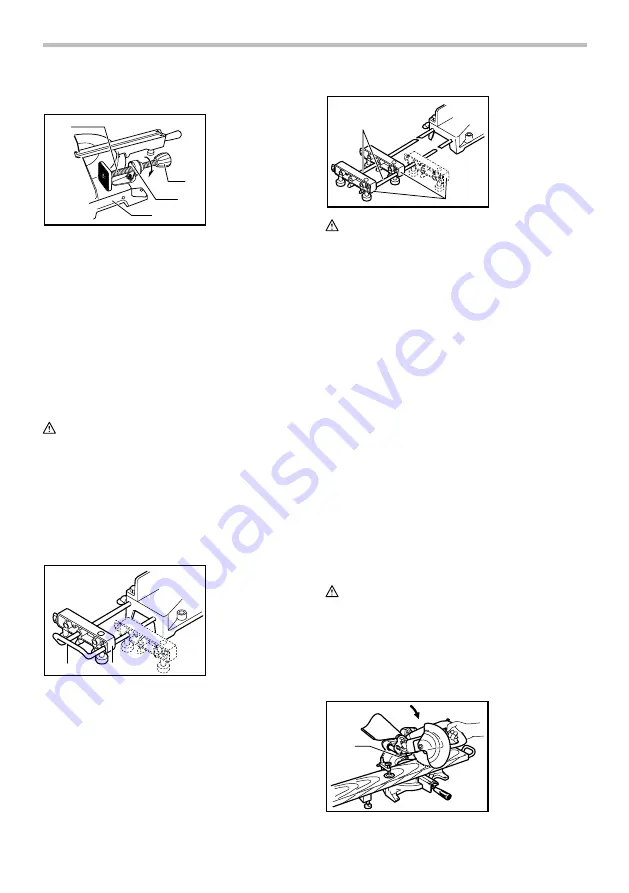

Holders and holder assembly

(optional accessories)

1

2

002247

The holders and the holder assembly can be installed on

either side as a convenient means of supporting

workpieces horizontally. Install them as shown in the

figure. Then tighten the screws firmly to secure the

holders and the holder assembly.

When cutting long workpieces, use the holder-rod

assembly (optional accessory). It consists of two holder

assemblies and two rods 12.

2

1

002246

WARNING:

•

Always support a long workpiece so it is level

with the top surface of the turn base for an

accurate cut and to prevent dangerous loss of

tool control.

Proper workpiece support will help

avoid blade pinch and possible kickback which may

result in serious personal injury.

OPERATION

NOTICE:

•

Before use, be sure to release the handle from the

lowered position by pulling the stopper pin.

•

Do not apply excessive pressure on the handle when

cutting. Too much force may result in overload of the motor

and/or decreased cutting efficiency. Push down handle

with only as much force as is necessary for smooth cutting

and without significant decrease in blade speed.

•

Gently press down the handle to perform the cut. If the

handle is pressed down with force or if lateral force is

applied, the blade will vibrate and leave a mark (saw

mark) in the workpiece and the precision of the cut will be

impaired.

•

During a slide cut, gently push the carriage toward the

guide fence without stopping. If the carriage movement is

stopped during the cut, a mark will be left in the

workpiece and the precision of the cut will be impaired.

WARNING:

•

Make sure the blade is not contacting the

workpiece, etc. before the switch is turned on.

Turning the tool on with the blade in contact with the

workpiece may result in kickback and serious

personal injury.

1.

Press cutting (cutting small workpieces)

1

011248

1. Clamp screw

1. Holder

assembly

2. Rod 12

1. Holder

2. Holder

assembly

1. Vise knob

2. Projection

3. Vise shaft

4. Base