44

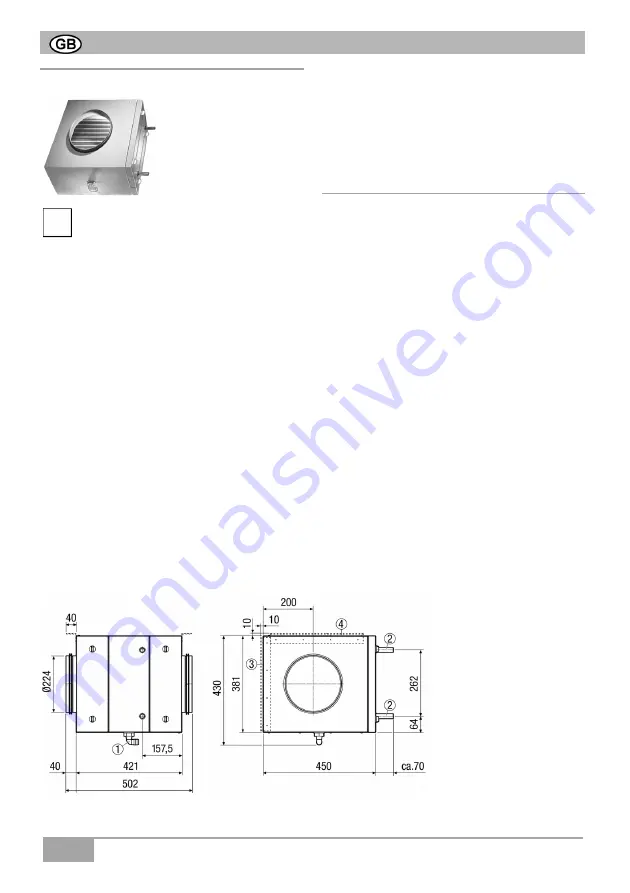

10.2 EW-K 225 brine register

Important notes

●

Installation work may only be carried out by

authorised specialists.

●

Take into account the planning documents

prepared by the engineering office and the

regulations valid where you are.

●

Take the Technical data listed in Chap-

ter 13 into account.

●

On-site work (run-off, floor construction,

etc) must all have been completed before

installation, as the EW-K 225 cannot be

moved again once the ducting is

connected.

●

Insulate the outside air ducts and brine

ductings

to prevent vapour diffusion for

energy-usage reasons and to prevent a

build up of condensation.

●

If installation is fitted outside the thermally

insulated building envelope, supply and

exhaust air ducts must also be insulated in

the cold area.

●

Additional insulation material should be

used to insulate fixing cuffs. This prevents

the build up of condensation.

●

Insulate the wall feedthroughs of the out-

side air ducts and brine ductings, in order

to exclude the possibility of a build-up of

condensation.

10.2.1 Connections and dimensions

●

Make sure that there can be no build up of

surface condensation with roof outlets.

●

Insulate the ventilation ducts with roof

outlets.

●

In order to avoid any smells, there should

be sufficient space between the outside air

inlet for the EW-K and the sewerage vent

on the roof.

●

The air filter can be mounted on the left or

right, depending on the installation position

(

→

Chapter 6.2, Changing the air filter).

NOTICE

Dirt build-up on unit compo-

nents during building work.

Only commission the unit once

all building work has been

completed.

NOTICE

Build up of condensation on

the heat exchanger

Drain off the condensation

correctly through a

condensation run-off with

siphon.

1

Condensation drain, 3/4"

2

Brine connection

Ø18 mm (forward and

return flow)

3

Wall-mounting bracket

4

Ceiling mounting

bracket

i