8 Installation and commissioning

29

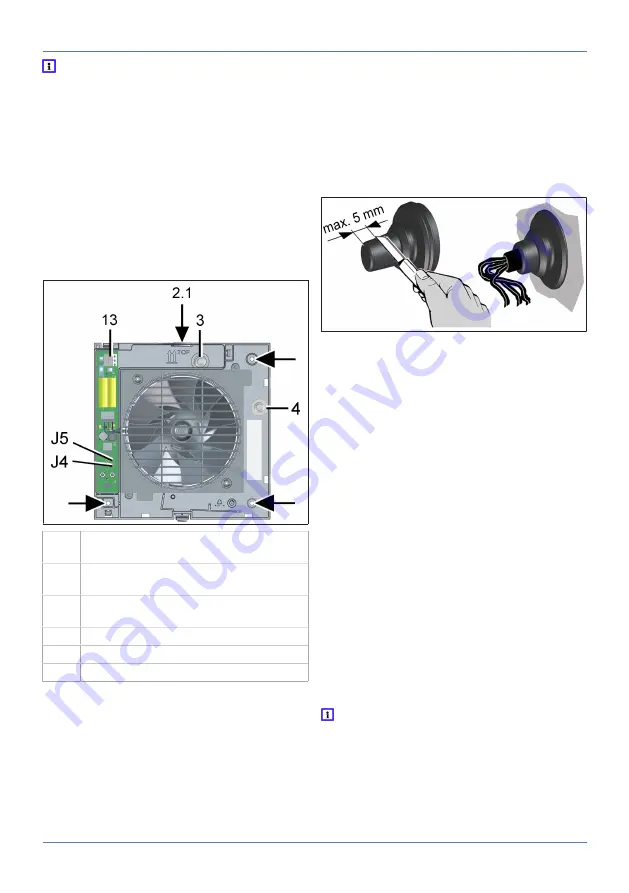

The foam strip must be fitted to the ECA

150 ipro H and KH, so that the units do not

draw in any infiltration air from outside.

4. For an electrical surface-mounted connection,

drill the housing segment [2.1] (→ following

figure) (Ø 11 mm).

8.2 Housing installation

NOTICE Damage to unit/functional problems

in the event of rubbing impeller.

Do not fit flange sleeve either twisted or crushed.

Make sure that the surface is flat.

1. Insert housing into wall breakthrough/wall

sleeve (TOP).

2.1 Housing segment – surface-mounted

connection

3 Cable grommet – flush-mounted connec-

tion

4 Cable grommet – surface-mounted con-

nection

13 Spring terminal

J4 Jumper J4

J5 Jumper J5

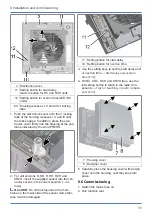

2. Align housing horizontally and mark the 3

dowel holes → arrows.

3. Drill dowel holes with a Ø of 6 mm and insert

dowels.

4. Carefully press the upper cable grommet out

of the housing and remove it. Alternatively, for

electrical surface-mounted connection, leave

the upper cable grommet in the housing and

remove the side cable grommet from the

housing.

NOTICE Danger of short-circuits / damage to

the unit. Water will penetrate if the power

cable is incorrectly fed into the fan housing or

if the cable grommet is not fitted correctly.

Cut off the cap of the cable grommet so that the

cable grommet tightly encloses the power cable.

Shorten the cap by a

max. of 5 mm

.

Fit cable grommet correctly, seal on site if re-

quired.

5. Insert cable grommet into housing.

6. Guide the power cable into the terminal com-

partment such that the cable grommet fits

around the cable sheathing completely.

7. Insert housing into wall breakthrough/wall

sleeve and secure with 3 screws. Do not insert

the housing such that it is twisted or crushed.

Make sure you use mounting material which is

sized for the purpose.

8.3 Electrical connection

NOTICE Risk of damage to unit in the event of

short-circuits.

Insulate PE conductor and individual cable cores

that are not required.

Do not touch electric components.

Master-slave operation of RC units is only

possible with similar types of ECA 150 ipro

RC/RCH/KRC/KRCH units.

1. Only lay single cable cores in the fan. To do

this, remove the power cable’s sheathing in

the terminal compartment. Strip single cable

cores to 9 to 10 mm.

2. Connect power cable to the spring terminal

→ .

The standard model of ECA 150 ipro can be

operated in two levels with double switches.

Without a double switch, the fan can be oper-

ated either at power level 1 or at power level 2

→ switching variants in chapter

.

3. Check the position of the cable grommets.

These must provide a good seal.