en

|

16

|

CWL-20E

Operation

8.10

Park mode

If desired, the load on the lift table can be transferred

from the air cylinder to the mechanical down stop

system by activating Park mode. Park mode also

automatically pins the lifts so that they act as stands.

The following steps explain how to activate Park mode.

1.

Follow the steps in Section 8.7 to position the vehicle

at the desired working height.

2.

Push and release the

ENABLE

button and within 5

seconds, push and release the

PARK

button. The lift

system will now lower until the down stop catch pawl

is supported on the down stop lug and the pin is

inserted on all lift units in the system.

NOTE

NOTE

NOTE

NOTE: The lifts will only park if they are all above the

same down stop lug. If they are not all above the

same down stop lug, the “park window error” will be

indicated and the lifts will have to be Raised or

Lowered until all the lifts are above the same down

stop lug.

3.

Once all the units in the system have Parked, the

PARKED

indicator will turn blue. The

LOWER

button

will also disappear since the vehicle will need to be

raised off the down stop lugs before it can be

lowered.

4.

To exit Park mode, simply push and release the

ENABLE

button and then within 5 seconds push and

hold the

RAISE

button until the

PARKED

indicator

light turns off. The vehicle can now be raised or

lowered normally.

8.11

Options

The

OPTIONS

button displays additional buttons that

are normally hidden from view on the screen. Pushing

the

OPTIONS

button displays a panel on the left side of

the screen that includes the

LOCK

button and the

ABOUT

button. To hide the panel that is displayed when

the

OPTIONS

button is pushed, push the

OPTIONS

button again.

The

LOCK

button is used as described in Section 8.7 to

lock the system from operating. Pushing the

ABOUT

button brings up a screen showing the contact

information for the lift manufacturer and the software

versions currently installed. To exit the About screen,

push the

ABOUT

button again.

8.12

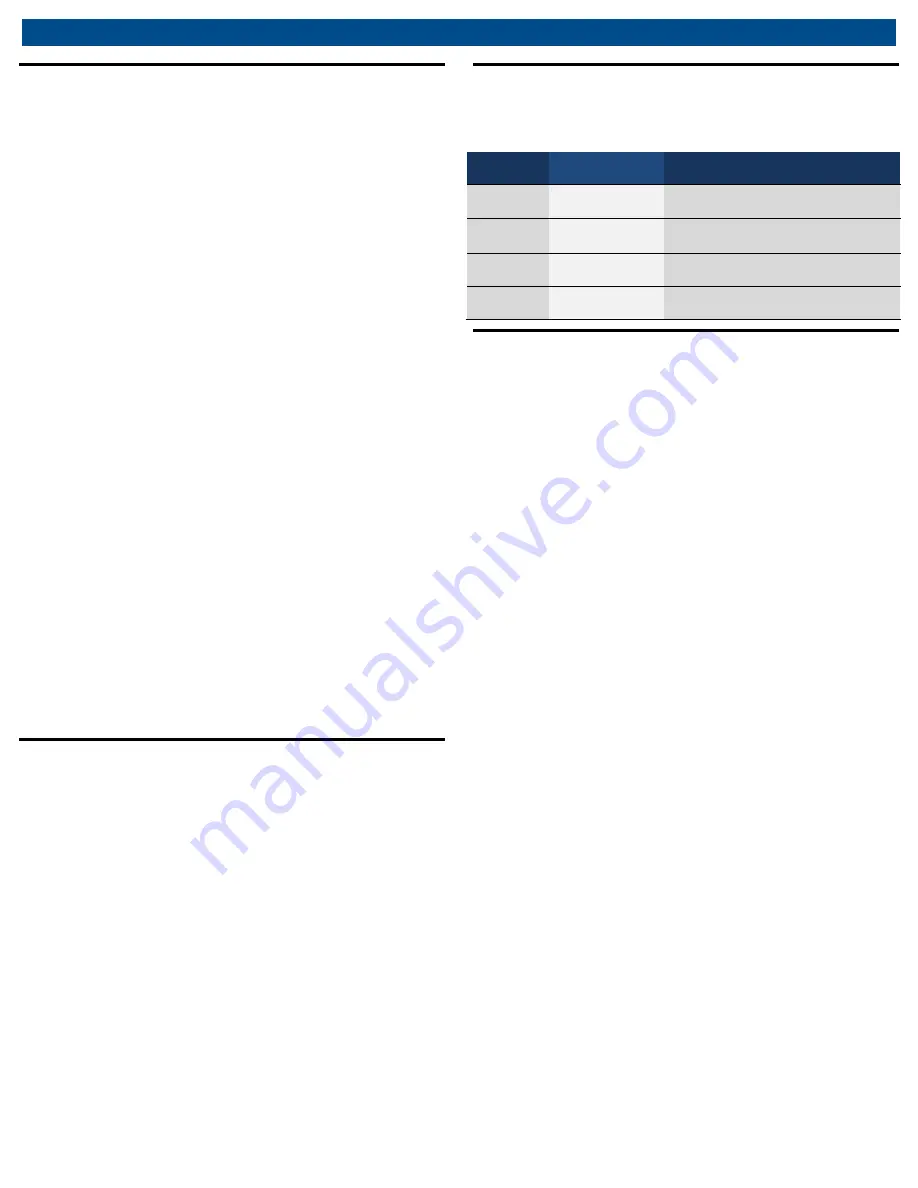

Status indicators

Shown below are the functions of the Status indicators

during operation of the lift system.

LED Color

LED State

Meaning

Green

Solid

•

The lift is set up

Green

Blinking

•

This lift is in communication with

the touch screen controller

Red

Solid

•

There is a fault in the system

Red

Blinking

•

There is a fault with this lift unit

8.13

Changing the touch screen frequency

on the lift units

1.

In order to change the touch screen frequency on a lift

unit, the Communication Button must be held while

the master on/off switch is turned to

ON

.

2.

When the Status Indicators rapidly flash, the

Communication Button should be released.

3.

When the Status Indicators stop rapidly flashing, the

lift unit is ready to change frequency. The current

frequency is indicated by the blink pattern shown with

the Status Indicators.

4.

The number of successive blinks between breaks is

the current frequency.

5.

Push the Communication Button to advance the

frequency to the desired frequency. Each push of the

button advances the frequency by one. If the

Communication Button is pushed when the frequency

is on 12, the frequency will jump back to 1.

6.

Make sure the desired frequency is chosen by

observing a full blink pattern. Once the desired

frequency is chosen, hold the Communication Button

until the Status Indicators rapidly flash and then

release the Communication Button.

7.

After the Status Indicators stop flashing, the

frequency is set and the lift is ready to be initialized.

The frequency blink pattern will continue to be

indicated until the Communication Button is pushed

to initialize the lift unit.