3 - Preventive Maintenance Procedure

ExpressCard 2000| Instant Issuance Card Personalization System | Preventive Maintenance Procedure

Page 22 of 25 (

D99875651-25

)

13)

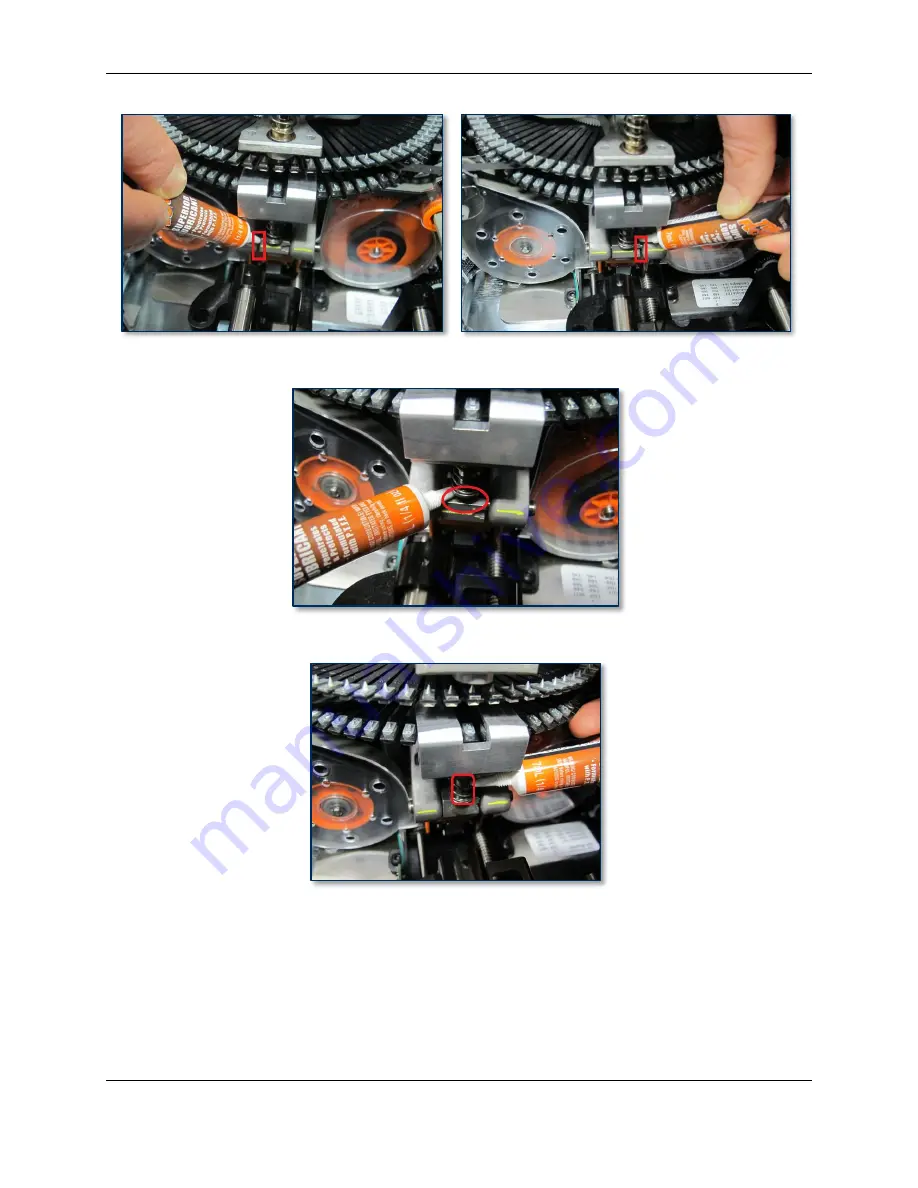

Add 2 drops of lubricant between bottom punch hammer and bottom hammer follower.

14)

Add 2 drops of lubricant to the front of the bottom punch hammer.

15)

Return the knuckles to the position they were in before lubricating.

16)

Test to make sure the top knuckle slides smoothly across the punch hammer: Press the top rocker

arm all the way down and make sure the top of the knuckle remains level and parallel to the floor at

all points in the movement cycle. The knuckle should not rotate from its initial orientation.