19

(CF20)

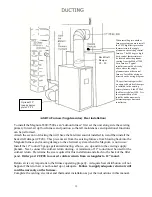

Add-On Furnace (Supplementary Heat installation)

To install the Magnum 6500/7500 as an “add-on furnace” first set the unit along side the existing

primary forced-air up flow furnace and position so that all maintenance and operational functions

can be performed.

Attach the section of ducting that will have the fan-limit control installed in it and then install the

back draft damper (CF20). This prevents air from the existing furnace from blowing back into the

Magnum furnace and causing damage to the electrical system when the Magnum is not in use.

Install the 12” round 26 gauge galvanized ducting, elbows, etc. up and into the existing supply

plenum. Next, connect the cold-air return ducting. A minimum of 12” round must be used for the

cold-air return. Determine the size required for this installation and attach to the back of the filter

panel.

Order part # CF28 to convert cold air return from rectangular to 12” round.

Return air is very important to the furnace operating properly. Adequate heat distribution will not

happen if the return air is not hooked up or adequate.

Failure to supply adequate return air will

void the warranty on the furnace.

Complete the venting, electrical and thermostat installation as per the instructions in this manual.

Back Draft

Damper

CF - 20

Optional 12”

round adaptor

plate CF-28

When installing into another

furnace system you must install

the CF29 high limit protection

thermostat into the supply

plenum on the existing central

furnace. The 200 degree high

limit control thermostat must

be located under the plenum

coming from the Model 7500

Corn furnace. Typical

installation would be directly

above where the supply

plenum starts on the central

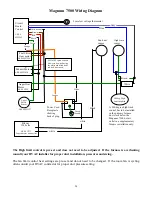

furnace. Install the wiring as

directed on the wiring diagram

UL specification require that

an approved back draft damper

is installed in the existing

primary furnace if the CFM of

the blower is below 1200. It is

the responsibility of the

installer and homeowner to

determine proper ductwork

installation.