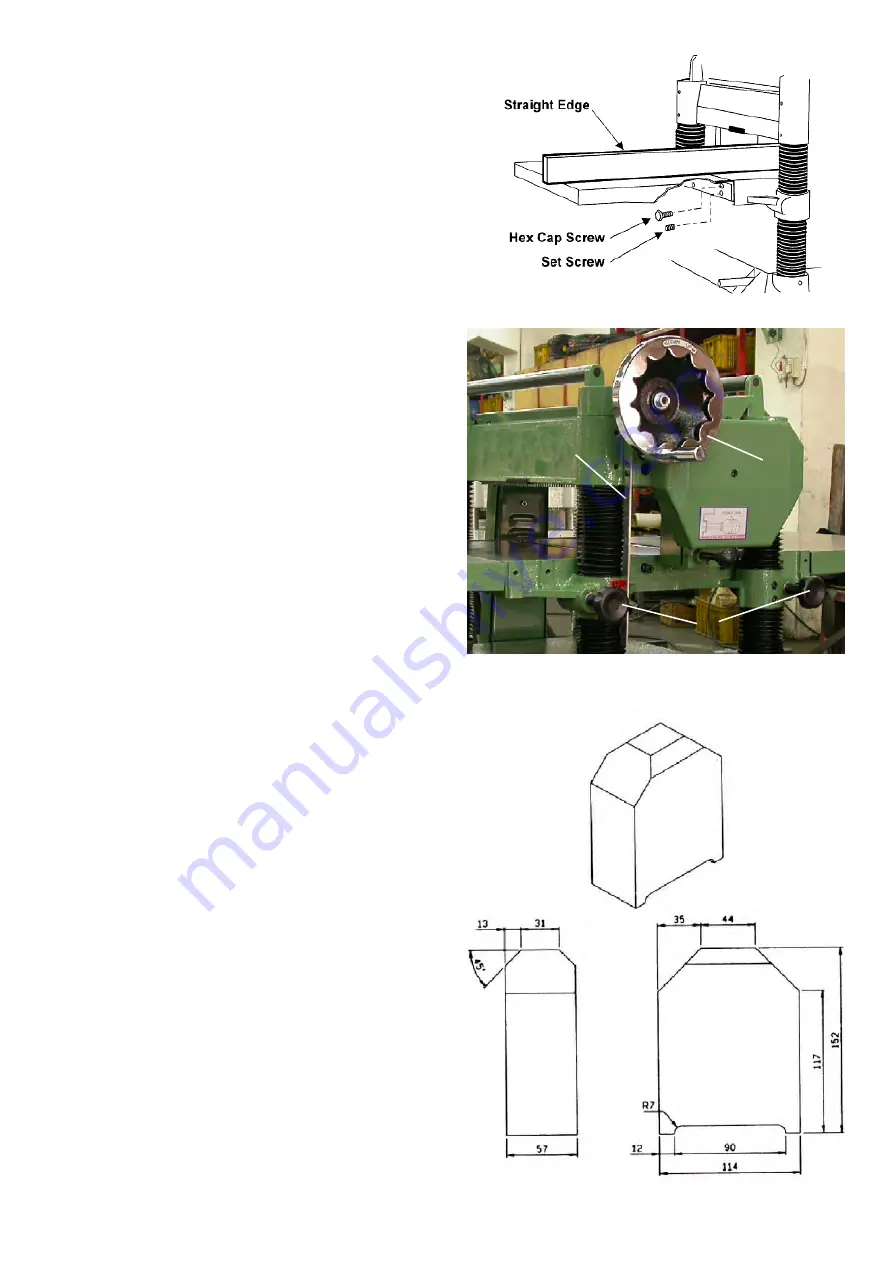

EXTENSION TABLES

1. Mount a cast iron table to the edge of the main

table with three M8 x 25 hex cap screws

(Fig. 17)

using a 12mm wrench. Do not fully tighten yet.

2. The extension table must be leveled with the

main table. Place a straight edge (such as a

jointed board) across both tables.

3. Insert three socket set screws with a 4mm hex

wrench, and screw them in or out as needed

until tables are level.

4. Securely tighten the hex cap screws.

5. Mount the second extension table to the opposite

side of the planer table, using the same

procedure.

Controlling The Depth Of Cut

The cutting depth scale is a combination inch/

metric scale (A), Fig. 18, cutting range from 0 to

8" (204mm). The distance of upward or downward

movement is controled by Handwheel (B) Fig. 18

for one evolution is 0.059" (1.5mm). Before mov-

ing table upward or downward, loosen the lock nuts

(C) as shown in Fig. 18. After choosing the proper

position, tighten the lock nuts (C),

Adjustments

Although your planer was carefully adjusted at the

factory, it should be checked before being put into

operation. Any inaccuracies due to rough handling

in transit can easily be corrected by following these

directions.

In order to check the adjustments you will need a

straight edge, feeler gage and a homemade gage

block made of hard-wood. This gage block can be

made by following the dimensions shown in Fig. 19.

Fig 19

Fig 18

Fig 18

C

B

A