MT55 18M bl

01/2022

15

4.4

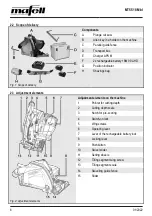

Chip extraction

Caution

Health hazards from wood dust

The dusts produced during work can be inhaled and can cause health damage.

➢

Harmful dust must be extracted with a HEPA 13 dust extractor.

➢

Wear a dust mask during work.

For all work that produces a significant amount of dust, connect the machine to a suitable external extraction

device. The air velocity must be at least 20 m/s [65 ft/sec].

The inner diameter of the hose connector is 35 mm [1.4 in].

For short-time work that generates a small amount of dust, you can use the shavings bag provided as a self-

suction device.

4.5

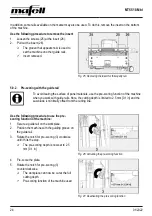

Saw blade selection

To achieve good cutting quality, use a sharp tool and select a tool from the following list that is appropriate for

material and application:

Cutting softwood and hardwood across and along the grain direction:

-

Carbide circular saw blade Ø 160 x 1.8 x 20 mm, 32 teeth [Ø 6.30 x 0.07 x 0.79 in]

Cutting softwood and hardwood especially along the grain direction:

-

Carbide circular saw blade Ø 160 x 1.8 x 20 mm, 16 teeth [Ø 6.30 x 0.07 x 0.79 in]

Cutting softwood and hardwood especially across the grain direction:

-

Carbide circular saw blade Ø 162 x 1.8 x 20 mm, 48 teeth [Ø 6.38 x 0.07 x 0.79 in]

Cutting softwood and hardwood especially across the grain direction "fine cuts":

-

Carbide circular saw blade Ø 160 x 1.8 x 20 mm, 56 teeth [Ø 6.30 x 0.07 x 0.79 in]

Cutting wood fiber insulation material:

-

Carbide circular saw blade Ø 160 x 1.8 x 20 mm, 32 teeth [Ø 6.30 x 0.07 x 0.79 in]

Cutting plastic material (styrofoam):

-

Carbide circular saw blade Ø 160 x 1.8 x 20 mm, 16 teeth [Ø 6.30 x 0.07 x 0.79 in]

Cutting fiber cement board:

-

Diamond saw blade Ø 160 x 3.0 x 20 mm, 4 teeth [Ø 6.30 x 0.12 x 0.79 in]