Page 5

For technical questions, please call 1-888-866-5797.

Item 62799

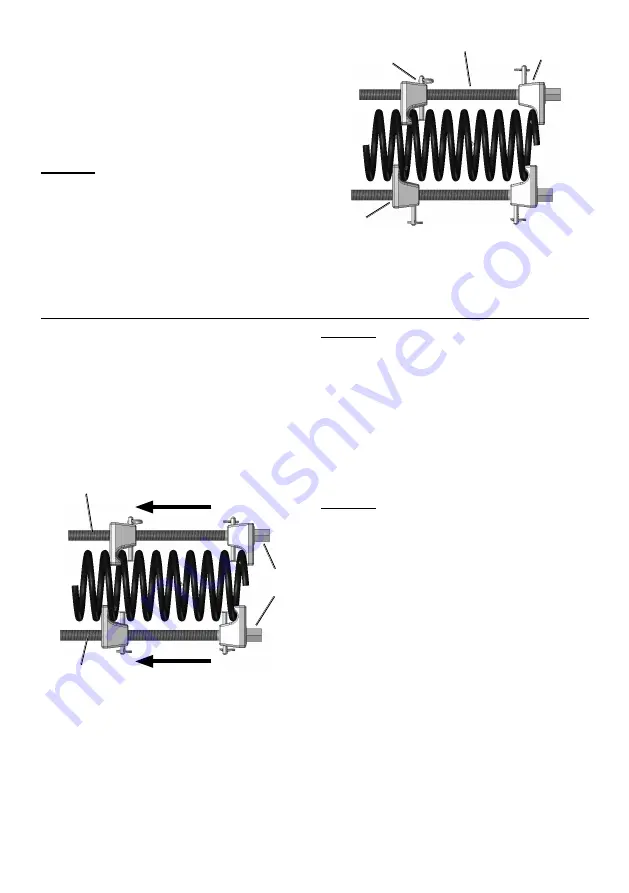

7. Push in the Locking Pins on both the Threaded and

Non-Threaded Puller Hooks until they snap into

locked position. Refer to Figure D and Figure E.

8. Repeat Steps 2 through 7 with the second

Strut Spring Compressor Assembly.

WARNING! Always use both Strut Spring

Compressors on the same spring,

at the same time.

Threaded

Puller Hook

Non-Threaded

Puller Hook

Screw

Locking Pin in

locked position

Figure D

Removing The Strut Springs

1. Check the Locking Pins to ensure they are

in the locked position. Refer to Figure E.

2. Rotate the strut assembly so the head

of the Screw can be easily accessed on

each Strut Spring Compressor.

3. Begin to tighten the head of the Screw on one Strut

Spring Compressor as shown in Figure E. Tighten

the Screw about one inch, then tighten the Screw of

the other Strut Spring Compressor an equal amount.

Screw

Screw

Head

Locking Pins

in locked

position

Screw

Figure E

WARNING! To prevent serious injury or DEATH from

the spring suddenly launching free:

Tighten the Screws EVENLY. Do not tighten

one Strut Spring Compressor all at once.

4. As the Screw on each Strut Spring Compressor is

tightened, the strut spring will begin to compress.

When the strut spring has been compressed

enough to allow free play of the coil spring on

the strut assembly, you may remove the strut

bearing nut at the top of the strut assembly

and remove the strut bearing and top hat. The

compressed strut spring can now be removed.

WARNING!

To reduce the pressure on

the spring and maintain better stability,

only tighten as much as is necessary.

5. If the Strut Spring Compressors have been tightened

as far as possible and there is no free play of the

coil spring on the strut assembly

, DO NOT REMOVE

the strut bearing nut. Remove the Strut Spring

Compressors evenly and place the Puller Hooks

further apart on the coil spring in order to compress

more of the coil spring. Repeat Steps 2 through 4.

6. Do not store a compressed coil spring for ANY

length of time, even if you are immediately replacing

the strut. Loosen the Screws on the Strut Spring

Compressors EVENLY to reduce pressure.