215922

370

Revision A

1022892

A

C

B

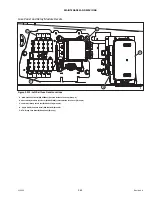

Figure 5.225: Drive Wheel Ready for Installation

5.

Position lifting device (A) under the wheel and raise the

wheel slightly.

6.

Position the wheel against the wheel drive hub so that air

valve (B) is on the outside while tread (C) points

cab-forward.

1011218

A

1

3

4

5

6

7

8

9

10

2

Figure 5.226: Tightening Sequence

–

10-Bolt Wheel

7.

Align the wheel rim with the studs on the hub. Push the

wheel onto the hub.

8.

Install and hand-tighten wheel nuts (A).

IMPORTANT:

To avoid damage to the wheel rims and studs, do

NOT

use

an impact wrench to tighten the nuts. The stud threads

must be clean and dry. Do

NOT

apply lubricant or anti-seize

compound to the stud threads. Do

NOT

overtighten the

wheel nuts.

9.

Torque the drive wheel nuts. For instructions, refer to

Tightening Drive Wheel Nuts, page 262

.

10. Repeat the tightening sequence two additional times, ensuring that the specified torque is achieved each time.

11. Repeat Step

to Step

in order to install the right drive wheel.

12. Raise the windrower, remove the stand, and lower the windrower to the ground.

13. Lower the windrower. Remove the jack. For instructions, refer to

Lowering Drive Wheel, page 370

.

14. Repeat the torque procedure every hour of operation until two consecutive checks confirm that there is no movement

of the nuts.

Lowering Drive Wheel

CAUTION

Jack stand must be capable of supporting a minimum of 2268 kg (5000 lb.).