800.MACTOOLS

7

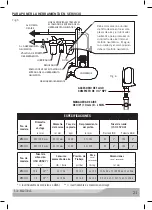

PROPER HAND POSITION

WARNING

Warning:

To reduce the risk of serious personal injury,

ALWAYS

use proper hand position as shown (Fig. 1).

Warning:

To reduce the risk of serious personal injury,

ALWAYS

hold securely in anticipation of a sudden reaction.

Proper hand position requires holding the air hammer, with both hands.

Fig. 1

MAINTENANCE

Lubrication

Air tools require lubrication throughout the lifetime of the tools.

The air hammer mechanism uses compressed air to power the tool. The compressed air contains moisture that

will rust the components inside of the tools, therefore lubrication is required daily. Failure to lubricate the air

tool properly will dramatically shorten the life of the tool and will void the warranty

CAUTION:

This air tool requires lubrication

BEFORE

initial use, also before and after each additional use.

To Lubricate The Air Tool Manually:

1. Disconnect the tool from the air supply source, place the air inlet face up.

2. Depress the trigger and place about 0.15 to 0.25 ml of air tool oil into the air inlet.

NOTE: Use SAE #10 weight oil if air tool oil is not available.

3. Connect the tool to an air source, place chisel against working surface, then cover the exhaust end with a

towel and run tool for 2 to 3 seconds.

WARNING

:

Keep out of the reach of children. If air tool oil is ingested, do not induce vomiting, call a doctor

immediately.

WARNING

:

Any excess oil in the tool is immediately expelled from the exhaust port. Always direct exhaust

port away from people or objects.

Storage:

The air tool must be lubricated before storing. Follow the “Lubrication” instruction with exception of step 3.

Always use an air line lubricator with this tool. Do not over-oil and do not use heavy grade

oil as stalling and low performance may result.