12

Your BV20 light bench lathe is a precision tool. In order to maintain this precision and prolong

its useful life, it is advised that you follow the recommended daily and periodic maintenance

tables printed below.

Installation / commissioning oil changing

1

st

oil change. Drain the gearbox and renew the oil after 35 hrs. running.

2

nd

oil change. Drain the gearbox and renew after 110 hrs. running.

Thereafter. Drain the gearbox and renew oil after every 350hrs. running.

Daily and periodic maintenance

Daily pre-use

1. Using an oilcan with a narrow nozzle, oil all the oil points on the machine. Inch

A) saddle (4), B) tailstock (2), C) traverse slide (1), D) compound slide (2), E) leadscrew

gearbox (2), and F) leadscrew end bearing (1)

2. Move the traverse and compound slides to give access to their drive shaft threads and

lightly coat with oil, work the oil up the threads to lubricate the thread followers.

3. Spray-oil the slides and the lathe bed, exercise the saddle and the slides to spread the oil

to all surfaces, both hidden and visible.

4. Spray up under the rack cover to lubricate the rack. (G)

5. Apply oil to the change gears and their axle mountings.(H)

Daily Pre-use

1.

Clean all swarf and chips away from the machine bed, slide surfaces, and the tool post.

2.

Exercise the slide and ensure no swarf etc., is lodged in the drive shaft tunnels.

3.

If you have been using ‘suds’ make sure the machine is thoroughly dried off. Clear the

suds tray of all swarf and chips, especially around the drain.

4.

Check the tool, ensure it is usable the next time, if not re-sharpen or replace the tool tip.

5.

Lightly oil spray all the machine beds and surfaces, and the tailstock barrel.

6.

Clean and lightly oil any tools you may have been using (centers, drill chucks, spanners

chuck keys etc, and put them away).

7.

Switch off the power supply. Disconnect the plug.

8.

Cover the machine over with a dust cloth.

Weekly

a) Check the belt tension.

b) Check the oil level in the gearbox.

c) Check the tautness of the slides.

d) Check the level of the suds reservoir. (if you are using suds).

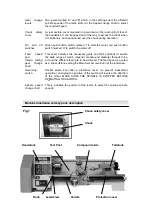

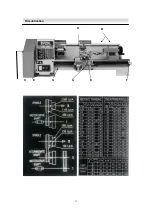

Bench lathe maintenance

Identification and Description of the parts of the BV20-BL Lathe

Summary of Contents for BL200L

Page 1: ...N Index of Contents BENCH LATHE BL200L BV20L OPERATION MANUAL ...

Page 10: ...10 ...

Page 14: ...14 ...