Use and functioning

24

IDM 510-074-1

English language

Operation and maintenance manual

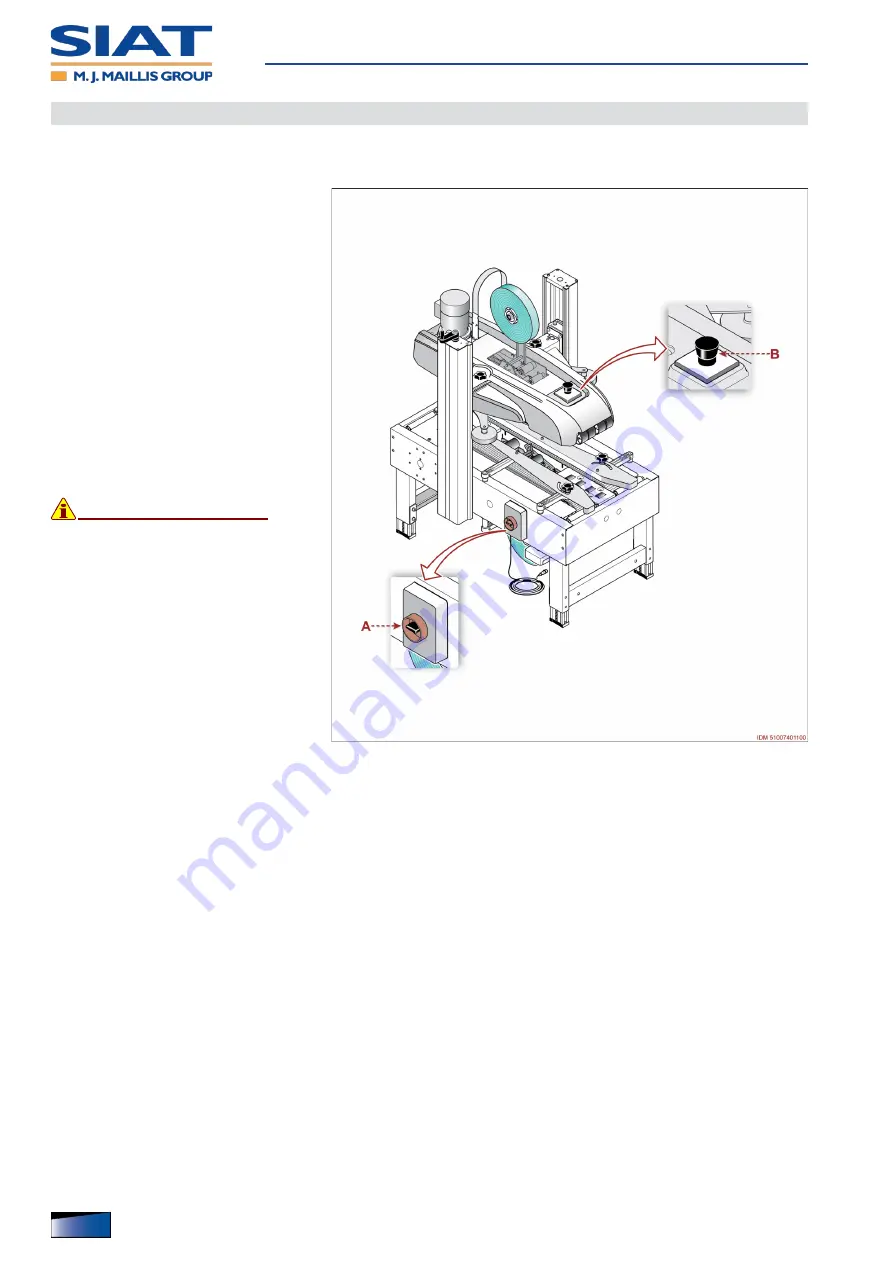

Emergency stop and new start-up

The figure shows the points of intervention and the description shows the proce-

dures to be adopted.

1.

In the presence of an imminent risk

press the emergency stop button

B

.

– All moving devices immediately stop.

–

Isolator switch A is automatically

positioned on “TRIPPED”.

2.

Rotate main disconnector

A

to posi-

tion

“O”

(OFF) to deactivate the

power supply.

3.

Identify the causes that have caused

the stop.

4.

Solve the malfunctions with respect

to the information shown in the man-

ual.

Important

The recovery operations that do not

fall within the competence of the op-

erator must be carried out by skilled

and authorised technicians.

5.

Unlock the emergency stop button

with a voluntary action.

6.

Turn the main disconnector

A

to po-

sition

“I”

(ON) to connect power sup-

ply.

– The conveyors (lower and upper)

start.