IO-360-N1A Engine Installation and Operation Manual

Requirements for Engine Installation

© 2016 Avco Corporation. All Rights Reserved

Page 14

February 2016

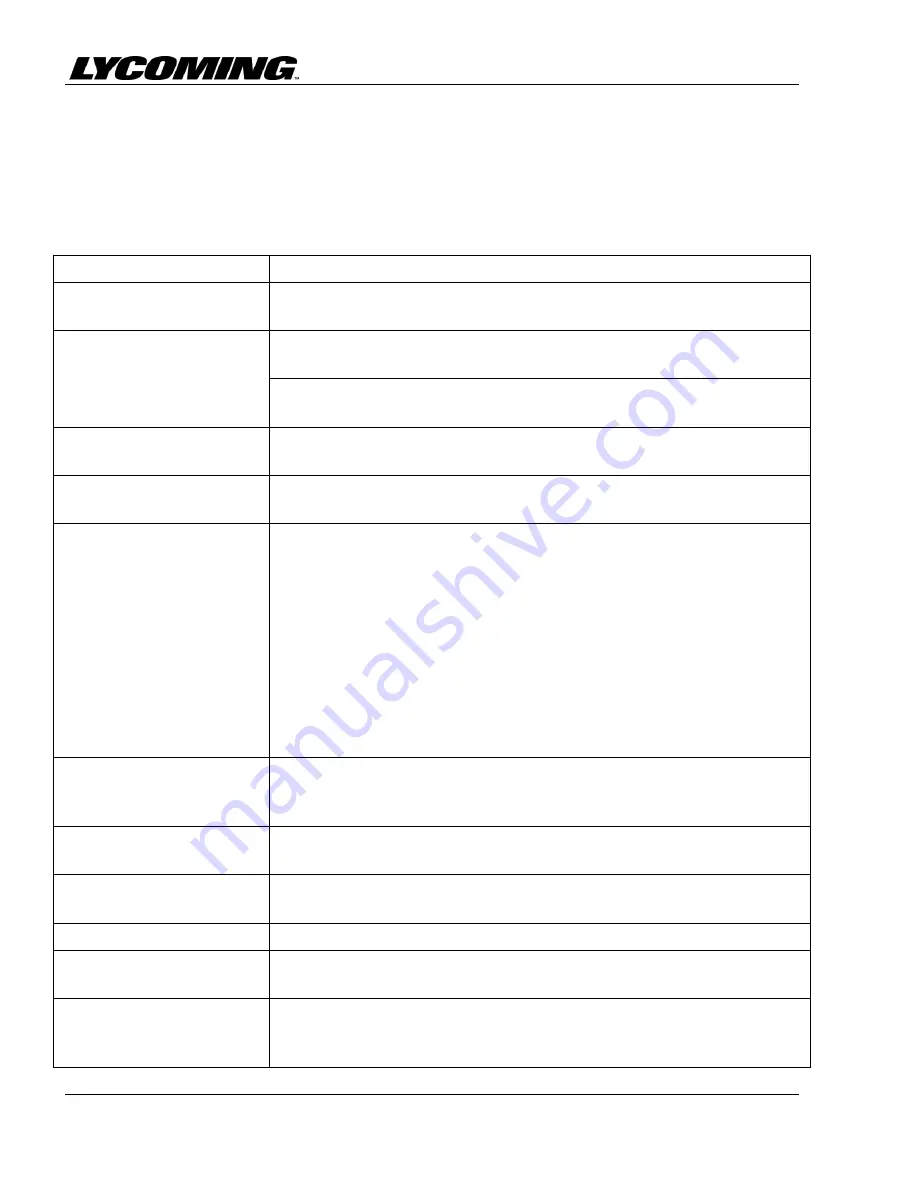

Step 2. Supply Interface Items

1.

Table 2 contains available equipment options, recommendations and requirements for the

airframe manufacturer to prepare for engine installation.

Table 2

Optional Equipment, Recommendations,

and Requirements to Prepare the Engine for Installation

Issue

Recommendation/Requirement

Installation drawings and

wiring diagrams

Installation drawings are available for purchase from Lycoming

Engines. Refer to Appendix B.

Magnetos

Refer to the magneto manufacturer's documentation for information on

various vibrator and switching arrangements.

If different magnetos, other than those identified in Appendix A, are

necessary refer to the latest revision of Service Instruction No. SI-1443.

Alternators

If a different alternator is necessary, refer to the latest revision of

Service Instruction No. SI-1154.

Cylinder head temperature

measurement

Airframe manufacturer-supplied bayonet thermocouples with AN-4076

fittings for installation on each cylinder head.

Oil Cooler

Provision is made for aircraft manufacturer-supplied full flow oil cooler.

Oil flow through the cooler system will be approximately 7.5 gallons

per minute (28.4 liters minute) and heat rejection will not exceed 820

Btu per minute. The oil cooler must withstand continuous pressure of

150 psi (1034 kPa) and have a minimum proof pressure of 400 psi (2758

kPa). A thermostatic bypass valve and pressure relief valve are optional.

The pressure relief valve limits the pressure drop between cooler

connections to 35 psi (241 kPa). The valve closes at 185ºF (85ºC)

routing all engine oil flow through the cooler. If pressure drop across the

oil cooler system is more than +75 psi (517 kPa) ±15 psi (103 kPa), the

pressure relief valve opens to bypass the cooler.

Oil pressure gage

There is a provision for installation by the aircraft manufacturer for

installation of an oil pressure gage connection (refer to the installation

drawing referenced in Appendix B.)

Fuel supply hose

Correctly-sized hose for the fuel pump supply and return vent line back

to the airframe.

Propeller Shaft

Conforms to specification AS127, Type 2 (Refer to the Installation

Drawing identified in Appendix B.)

Mounting

Rear Type 1 dynafocal mounting – four mounting bosses

Air cleaner

Air cleaner at rated power is 1150 lb of air per hour; pressure drop not to

exceed 6 in. of water.

Exhaust collector

There is a provision for the airframer to install an exhaust collector.

Stainless steel or low carbon steel-type exhaust flanges are available as

optional equipment.