LVO Manufacturing, Inc.

LVO Manufacturing, Inc.

LVO Manufacturing, Inc.

LVO Manufacturing, Inc.

808 N. 2

nd

Avenue E., P.O. Box 188

Rock Rapids, IA 51246

www.lvomfg.com

(712) 472-3734

1-800-346-5749 Fax (712) 472-2203

__________________________________________________________________________________________________________________________________________________________________

17

Preventative Maintenance

● Turn off power and drain machine, making sure it drains freely.

● Check machine for general cleanliness. Make sure the pump screen and scrap trays are clean and

properly in place. Wash heating elements (electric models only) must be cleaned on a daily basis

for proper operation. Check for plugged wash and rinse nozzles. If necessary, the entire wash arm

assembly can be removed by pulling out the grip ring pin and sliding the assembly out of the hub.

These items are part of the daily maintenance schedule.

○ Check for excessive play in the hub/wash arm assemblies. Excessive wear can affect the wash

pressure and shorten the life of some hub components. Hub repair kits are available from the

factory.

○ Close drain valve and fill machine, making sure drain does not leak (some water may initially run

out of the drain through the overflow). Run through a Light, Medium, and Heavy wash cycle,

checking for proper timer operation.

● Check if Power, Wash, and Rinse lights are working.

● Check if pump pressure during wash cycle is within recommended range (45-60 psi).

● Check if rinse pressure is approximately 20 psi. Note: This must be checked during rinse cycle for

accurate reading.

○ Make sure steam exhaust fan is working properly. See

Step 6

in the Installation Instructions for

proper operation.

● Allow machine to heat up to recommended temperatures, making sure the temperature controls are

operating properly. Wash temperature and Rinse Tank temperature should be noted at this time.

The rinse water temperature gauge is accurate only during rinse cycle and should be checked

while machine is rinsing.

Note: If a qualified technician is available, current readings for heating elements should be taken

to ensure they are heating properly.

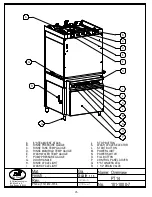

○ Machines with slide-up doors, door cables and connections should be inspected for damage or

excessive wear and replaced if necessary. Make sure cable pulleys turn freely and door switch is

still adjusted properly.

○ Pump motor(s) should be greased occasionally depending on usage. Once or twice yearly should

be sufficient under normal use.

Note:

Items above marked ● are easily identified visually and should be checked on a daily basis. Other

items should be checked periodically, depending on usage.

Time required for complete inspection may vary, depending on wash timer settings, heat up time, etc.

One to two hours is a reasonable amount of time unless problems are encountered that need attention.

If any problems or questions arise, call the factory for assistance.