AIR6V 01

AIR6V 01

AIR6V 01

AIR6V 01

SG900 06

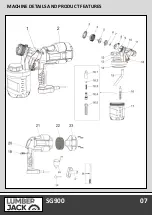

MACHINE DETAILS AND PRODUCT FEATURES

Machine Details

Specifications:

Mains Voltage -230V / 50Hz

Power– 500W

Water Flow Rate – 900ml/min

Viscosity Measuring – 100DIN-s

Nozzle Size –Ø2.0mm

Canister Capacity – 900ml

Gross Weight – 2.0kg

Nett Weight – 1.5kg

Package Contents:

Spray gun

Viscosity measuring

Nozzle cleaning needle

Cleaning brush

Nozzle tip spanner

Intended Use

This spray gun is ideal for refinishing a wide

variety of purposes. The intended use

includes the mechanical spraying of liquid,

paste or powdery substances such as paints

containing solvents or water-based paints

on components, surfaces, etc.

The product may not be used for

processing emulsion and latex paints or

chlorinated solutions.

For safety reasons it is essential to read the

entire instruction manual before first

operation and to observe all the

instructions therein.

This product is intended for private

domestic use only, not for any commercial

trade use. It must not be used for any

purposes other than those described.

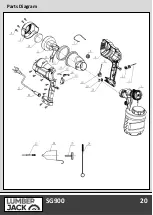

Product Features

1.Spray gun unit

2.Power unit

3.Smart nozzle selector

4.Tip collar

5.Air cap

6.Nozzle

7.Y-type seal ring

8.Spray width lever

9.Spray tip

10.Spray unit housing

11.Trigger

12.Quick refill lid

13.sealing linear

14. O-ring

15. Pickup tube

16. Check valve assembly

16.1 Check valve sleeve 1

16.2 Check valve

16.3 Spring

16.4 Check valve sleeve 2

16.5 Valve extension

17. Canister

18. Flow control knob

19. Quick release lock

20. Switch trigger lever

21. Hanging hook

22. Filter

23. Filter cover

24. Viscosity cup

25. Cleaning

needle

26. Cleaning brush

27. Spray tip key