1. Know your smartALIGN

2. Mount smartALIGN and switch on

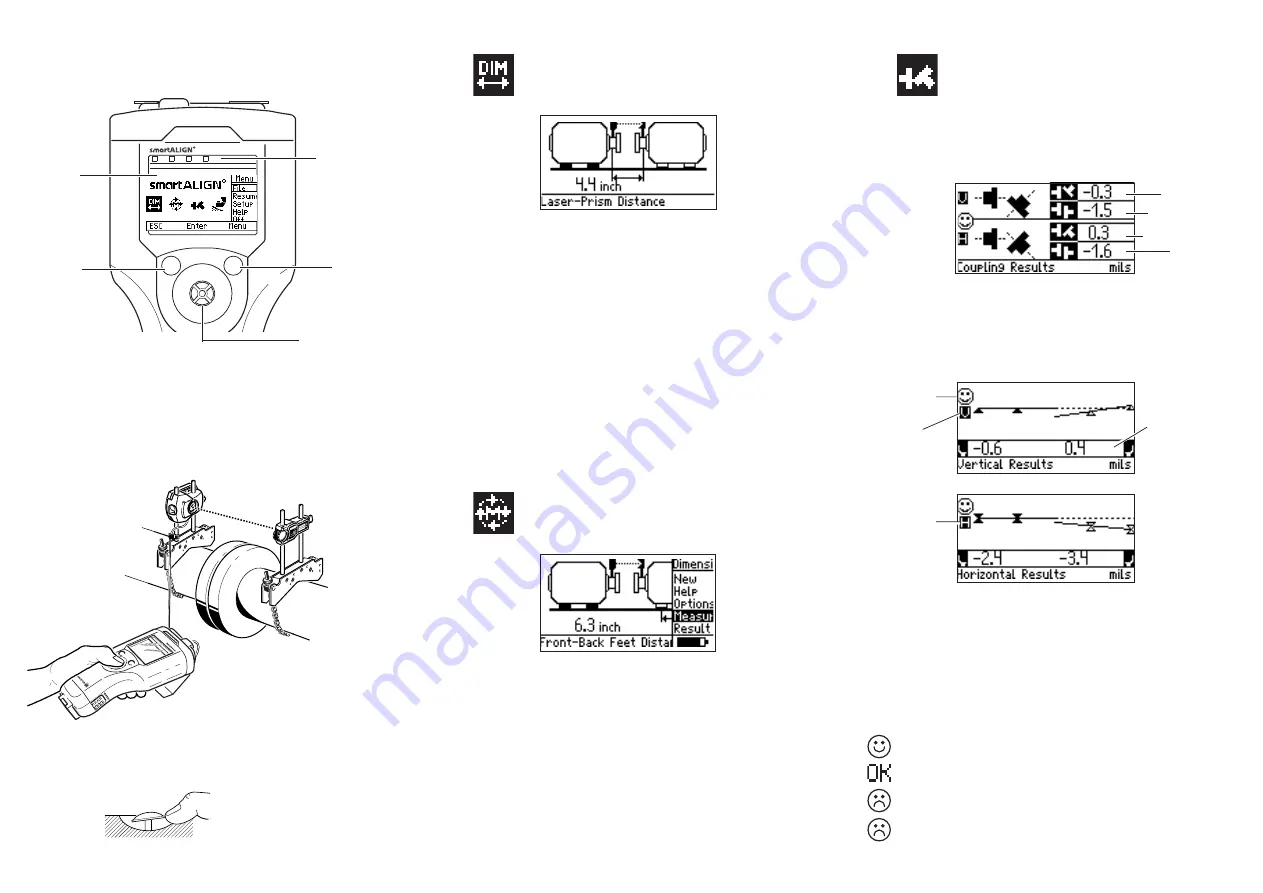

3.

Enter dimensions

The main operating buttons are the joystick, the menu button

and the escape button.

4.

Measure

From the start screen, select the dimensions icon. Depress joystick

to enter machine dimensions. The rectangular box appears when

the joystick is pushed forwards or backwards. Proceed to edit di-

mension by moving the joystick forwards, backwards and/or side-

ways.

Dimensions to be entered include:

•Laser-to-prism

•Laser-to-coupling center (calculated automatically from laser-prism

distance, or distance to right side of spacer coupling)

•Coupling diameter

•RPM

•Laser-to-front foot (of right machine)

•Front foot-to-back foot (of right machine).

When the dimensions have been entered, the dimensions submenu

appears with ‘Measure’ highlighted.

With the cursor on ‘Measure’, depress joystick to proceed with

measurement. Measurement can also be started by selecting the

measure icon in the start screen.

Center the laser beam using the reflector thumbwheel and the

yellow knob. When the beam is centered, the blue LED lights up.

As the default measure mode is continuous sweep, this mode is

automatically initiated when the shafts are rotated. After a rota-

tion of at least 60°, the results option is highlighted. Depress joy-

stick to view alignment results.

5.

Results

Access the submenu item ‘Results’ by pressing the menu button.

With ‘Results’ highlighted, depress joystick to obtain results. Re-

sults can also be accessed by selecting the results icon in the start

screen.

Coupling results are given in the form of gap difference at the

entered coupling diameter and offset.

With left machine stationary, gap is positive when open at top or

side away from viewer

Foot results are accessed by moving joystick.

Vertical gap

Vertical offset

Horizontal gap

Horizontal

offset

Both vertical and horizontal results show the foot position relative

to the stationary machine centerline.

Positive values indicate that machine foot is upwards or away from

viewer. Negative values indicate that machine is downwards or

towards the viewer.

The alignment condition is indicated by both the tolerance sym-

bol and the corresponding lit smartALIGN LED.

Horizontal

Foot positions

Tolerance

symbol

Vertical

Switch on the instrument by pushing the joystick forward and

holding for a few seconds. All 4 computer LEDs light up.

Stationary

machine

Machine to

be moved

Transducer (Laser)

Reflector (Prism)

smartALIGN

computer

Joystick pushed to

turn on smartALIGN

LEDs

Escape

button

Menu

button

Joystick

Start

screen

With blue LED lit - values within excellent tolerances

With green LED lit - values within acceptable tolerances

With amber LED lit - values out of tolerance

With red LED lit - machine misaligned