Related Manual

Read this data sheet carefully prior to any operation, mounting, installation or start-up of the

product.

Name

Code

GLOFA-GMWIN Programming software

10310000318

GLOFA-GMWIN Instruction & Programming

10310000377

GLOFA-GM/MASTER-K Smart I/O User’s manual

10310000353

GLOFA-GM Pnet I/F Module User’s Manual

10310000334

KGLWIN(Programming software)

10310000345

MASTER-K Instruction & Programming

10310000346

XG5000 Programming software

10310000512

XGK/XGB Instruction & Programming

10310000510

XGI/XGR/XEC Instruction & Programming

10310000833

XGK CPU series

10310000508

XGI CPU series

10310000832

XGB Hardware

10310000893

XGB Hardware (IEC)

10310000981

XGT Pnet I/F Module User’s Manual

10310000636

Smart I/O user manual

10310000353

Revision History

Publication

Version

Description

2003.07.

V1.0

The first edition

2005.06.

V1.1

Head office address and Group CI changed

2009.08.

V2.0

Branch address changed

2011.05

V3.0

KOREAN/ENGLISH data sheet integrated

CI Changed

2013.11

V3.1

Terminal block screwing torque added

Domain of Homepage changed

2014.04

V3.2

Terminal block drawing edited.

1. General Specifications

No

Item

Specification

Standard

1

Operating

temperature

0 ~ 55

℃

-

2

Storage

temperature

-25 ~ 70

℃

-

3

Operating

humidity

5 ~ 95%RH, non-condensing

-

4

Storage

humidity

5 ~ 95%RH, non-condensing

-

5

Vibration

resistance

For discontinuous vibration

-

-

Frequency

Acceleration

Amplitude

times

IEC61131-2

10≤f

∠

57 Hz

-

0.075 mm

10 times in

each

direction

for

X, Y, Z

57 ≤f≤150 Hz 9.8

㎨

(1G)

-

For continuous vibration

Frequency

Acceleration

Amplitude

10≤f

∠

57 Hz

-

0.035 mm

57≤f≤150 Hz 4.9

㎨

(0.5G)

-

6

Shocks

resistance

•

Max. impact acceleration : 147

㎨

(15G)

•

Authorized time : 11

㎳

•

Pulse wave : Sign half-wave pulse

(Each 3 times in X,Y,Z directions)

IEC61131-2

7

Noise

resistance

Square wave

impulse

noise

AC: ±1,500V

DC: ±900V

LSIS

standard

Electrostatic

discharge

Voltage: 4kV (Contact discharge)

IEC61131-2

IEC61000-4-2

Radiated

electromagnetic

field noise

80 ~ 1,000 MHz, 10 V/m

IEC61131-2

IEC61000-4-3

Fast transient

/burst noise

Segment

Power

supply

module

Digital/analog

input/output

communication

interface

IEC61131-2

IEC61000-4-4

Voltage

2 kV

1 kV

8

Ambient

conditions

No corrosive gas or dust

-

9

Operating

height

2000m or less

-

10

Pollution

degree

2 or less

-

11

Cooling

type

Natural air cooling

-

2. Performance Specifications

Items

Performance spec.

GPL-D22C/D24C/DT4B/C/TR2B/C/TR4B/C/RY2C

Transmission

spec.

Standard

EN50170 / DIN 19245

Interface

RS-485(Electric)

Media Access

POLL

Topologe

BUS Type

Encording Method NRZ

Cable type

Twisted Pair Shielded Cable

Comm. Distance

1200m(9.6k ~ 187.5 kbps)

400m(500kbps)

200m(1.5Mbps)

Max. Node

number

99

Max. Node

number

(per segment)

32

Max. I/O Data

Input : 4Byte / Output : 4Byte

Basic spec

External current

consumption(mA)

GPL-D22C : 70 / GPL-D24C : 85

GPL-DT4B/C : 100 / GPL-TR2B/C : 85

GPL-TR4B/C : 115 / GPL-RY2C : 160

Weight(g)

GPL-D22C : 188 / GPL-D24C : 286

GPL-DT4 B/C : 254/284 /GPL-TR2 B/C : 160/189

GPL-TR4 B/C : 255/285 / GPL-RY2C : 332

3. Cable Specifications

(1) Belden Network Cable

(a) Type : Network Components

(b) Protocol : FMS-DP-PA

(c) Certification : No

(d) Order No. : 3077F, 3079A

Item

Twinax

AWG

22

Type

BC-Bare Copper

Insulation

Method

PE-Polyethylen

Insulation

Thickness

0.035 (Inch)

Shield

Aluminum Foil-

Polyester Tape/Braid

Shield

Capacity

8500

㎊

/ft

Characteristic

Impedance

150

Ω

Core

2 Core

(2) Connector

4. Wiring of communication cable

(1) Wiring and Termination

(a) Please connect a GREEN line to A1,A2 and a RED line to B1,B2 in general.

In addition, Shield is connected to the clamp of connector.

(b) Please use cable of over 80% shield density.

(c) Please ensure that you have terminated both ends of each segment.

(d) If there are more than 0ne segment, it is necessary that you should

terminate every segment.

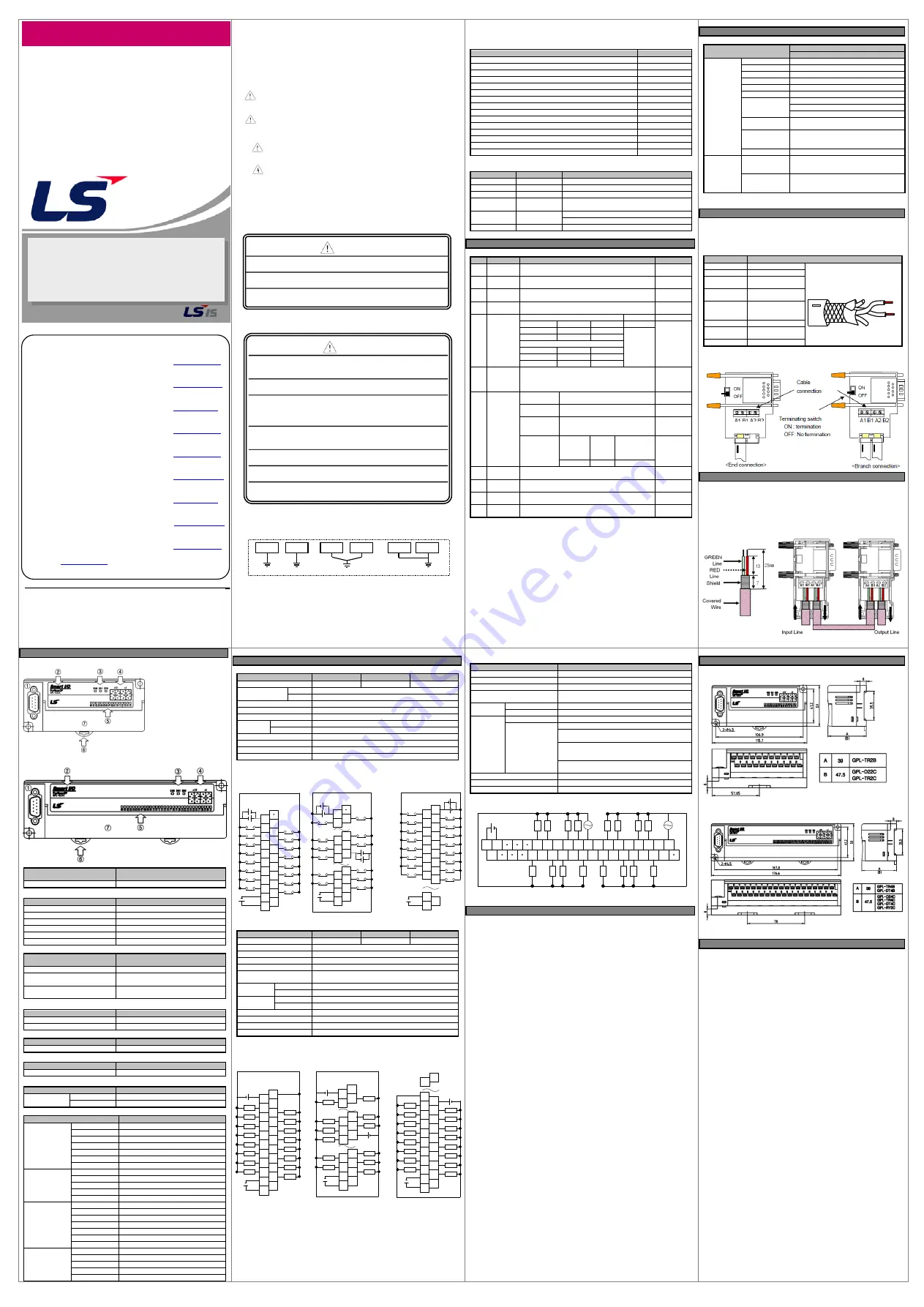

5. Parts Name and Descriptions

(1) GPL-D22C/TR2B/TR2C

(2) GPL-D24C/DT4B/DT4C/TR4B/TR4C/RY2C

Connector

Connector for connecting with

communication module

9-PIN Plug

9-pin female connector for Pnet

Part name display section

Display the Part name of Smart I/O

GPL-D22C

DC Input 16

GPL-D24C

DC Input 32

GPL-DT4B/DT4C

DC Input 16//TR Output 16

GPL-TR2B/TR2C

TR Output 16

GPL-TR4B/TR4C

TR Output 32

GPL-RY2C

RELAY Output 16

Communication LED

Display the status of communication

module

RUN

Display the status of power

RDY

Displays the communication status of

Comm. Module

ERR

Displays the abnormal err of comm..

module

Station Switch

0 ~ 99 (0:Reserved)

×

10

Set 10 digit of station number

×

1

Set 1 digit of station number

LED display section

Display the ON/OFF status of module

LED(0~15, 0~31)

Display the ON/OFF status of module

HOOK

HOOK

HOOK

Hook for mounting on DIN Rail

Screwing Part

Screwing Torque

Terminal block

screw

Screw tightening 3.7 kgf above

Screw loosening 3.7 kgf above

Terminal Block

In/Output terminal & Power input

GPL-D22C

/

GPL-D24C

0 ~ 15

Input terminal(GPL-D22C)

0 ~ 31

Input terminal(GPL-D24C)

COM

Common(16 points/COM)( GPL-D22C)

COM0/COM1

Common(16 points/COM)( GPL-D24C)

FG

Frame Ground

DC 24V

+24VDC Input terminal

DC 24G

-24VDC Input terminal

GPL-DT4B

/

GPL-DT4C

0 ~ 15/0 ~ 15

Input/Output terminal

COM0/COM1

Common(16 points/COM)

FG

Frame Ground

DC 24V

+24VDC Input terminal

DC 24G

-24VDC Input terminal

GPL-TR2B/C

/

GPL-TR4B/C

0 ~ 15

Output terminal(GPL-TR2B/TR2C)

0 ~ 31

Output terminal(GPL-TR4B/TR4C)

COM

Common(16 points/COM) (GPL-TR2B/C)

COM0/COM1

Common(16 points/COM) (GPL-TR4B/C)

FG

Frame Ground

24V

+24VDC Input terminal

24G

-24VDC Input terminal

GPL-RY2C

0 ~ 15

Output terminals

COMA~COMD

Common(8 points/COM)

FG

Frame Ground

DC 24V

+24VDC Input terminal

DC 24G

-24VDC Input terminal

6. Specification of Input/Output Module

(1) GPL-D22C/D24C/DT4B/DT4C(Input)

Specifications

GPL-D22C

GPL-D24C

GPL-DT4B/C

Number of input points

16 points

32 points

16 points

Rated Input

Current

B

7 mA

C/C1

5 mA

Operating Voltage Range

DC 20.4~28.8V(ripple: less than 5%)

ON Voltage

DC 19V or less

OFF Voltage

DC 6V or less

Response

Time

OFF

→

ON

0~3ms or less

ON

→

OFF

0~3ms or less

Common Terminal

16 points/COM

Operating indicator

LED turns on at ON state of input

External connections

Terminal block connector(M3

×

6 screws)

Insulation Method

Photo Coupler

(a) External Connection

<GPL-D22C> <GPL-D24C> <GPL-DT4B/C>

15

13

11

09

07

05

03

01

DC

24G

DC

24V

14

10

08

06

04

02

00

COM1

FG

12

+

+

-

-

13

11

09

07

05

03

01

DC

24G

DC

24V

10

08

06

04

02

00

COM

FG

12

15

COM

14

+

-

+-

+

-

+

-

30

18

16

15

03

01

DC

24G

DC

24V

31

17

04

02

00

FG

19

+

+

-

-

COM1

COM0

+ -

+

-

+

-

(2) GPL-TR2B/TR4B/DT4B/TR2C/TR4C/DT4C(Output)

Specifications

GPL-TR2B/C

GPL-TR4B/C

GPL-DT4B/C

Number of output points

16 points

32 points

16 points

Rated load voltage

DC 24V

Max. load current

0.5A/point, 3A/COM

OFF leakage current

0.1mA or less

Max. inrush current

4A /10ms or less

Maximum voltage drop

at ON circuit

DC 1.0V or less

External

Power supply

Voltage

DC 24V

±

10%(ripple voltage : 4Vp-p or less)

Current

30mA(TYP. All points On)

Response

Time

OFF

→

ON

1ms or less

ON

→

OFF

1ms or less

Common Method

16 points/COM

Operating Indicator

LED turns on at ON state of output

External connections

Terminal block connector (M3

×

6 screws)

Insulation method

Photo coupler

(a)

External Connection

<GPL-TR2B/C> <GPL-TR4B/C> <GPL-DT4B/C>

15

COM1

0V

13

11

09

07

05

03

01

DC

24G

DC

24V

10

08

06

04

02

00

FG

12

L

15

COM0

14

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

+ -

+

-

30

18

16

15

03

01

DC

24G

DC

24V

0V

31

17

04

02

00

FG

19

COM1

COM0

+

-

+ -

L

L

L

L

L

L

L

L

L

L

L

L

+

-

13

11

09

07

05

03

01

DC

24G

DC

24V

0V

10

08

06

04

02

00

COM

FG

12

L

15

COM

14

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

+

-

+

-

(3) GPL-RY2C

Specification

GPL-RY2C

Number of output points

16 points

Rated load voltage/current

DC24V/AC220V, 2A(Cos

ϕ

=1)/point 5A/COM

Minimum load voltage/current

DC 5V/1mA

Minimum load voltage/

Maximum switching frequency

AC 250V DC 110V, 1,200 times/hour

Response

Time

OFF

→

ON

10ms or less

ON

→

OFF

12ms or less

Service

Life

Mechanical

20 million times or more

Electrical

Rated load voltage/current 100,000 times or more

AC 200V/1.5A,AC 240V/1A(Cos

ϕ

=0.7) 100,000 times

or more

AC 200V/1A,AC 240V/0.5A(Cos

ϕ

=0.35) 100,000

times

or more

DC 24V/1A,DC 100V/0.1A(L/R=7ms) 100,000 times

or more

Common Method

8 points/COM

Operating Indicator

LED turns on at ON state of output

External connections

Terminal block connector(M3

×

6 screws)

(a) External Connection

DC

24V

DC

24G

01

02

05

06

09

10

13

14

COMA

COMA COMA

COMC

COMC COMC

FG

03

04

07

08

11

12

15

COMB

COMC

COMC

COMD

COMA

00

COMA

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

+ -

* Internally, The COMA and COMC are wired each other.

7. Precaution on installation

(1) When setting up the network, be sure not to duplicate the station number.

If there is any duplicated station number, the communication will not be established.

(2) Use cable complied with specification of this data sheet. Otherwise, it can cause serious

communication error.

(3) Make sure that communication cable connector fastened firmly. Otherwise, it can cause

serious communication error.

(4) Improper cable connection (snarled cable, redundant connection, etc) can cause

communication error.

(5) Do not place communication cable near power cable or inductive noise source.

(6) Change of station number will not take effect before power is re-applied.

8. Dimension (

㎜

)

(1) GPL-D22C/TR2B/TR2C

(2) GPL-D24C/TR4B/TR4C/DT4B/DT4C/RY2C

9. Warranty

(1) Warranty period

LSIS provides an 18-month-warranty from the date of the production.

(2) Warranty conditions

For troubles within the warranty period, LSIS will replace the entire PLC or

repair the troubled parts free of charge except the following cases.

(a) The troubles caused by improper condition, environment or treatment

except the instructions of LSIS.

(b) The troubles caused by external devices.

(c) The troubles caused by remodeling or repairing based on the user’s own

discretion.

(d) The troubles caused by improper usage of the product.

(e) The troubles caused by the reason which exceeded the expectation from

science and technology level when LSIS manufactured the product.

(f) The troubles caused by natural disaster.

(3) This warranty is limited to the PLC itself only. It is not valid for the whole system

which the PLC is attached to.

•

HEAD OFFICE

LS Tower, 127, LS-ro, Dongan-gu, Anyang-si,Gyeonggi-do, 431-848, Korea

Tel: 82-2-2034-4870

Fax: (82-2)2034-4648

e-mail:

•

LSIS(ME) FZE _ Dubai, U.A.E.

Tel: 971-4-886-5360

Fax: 971-4-886-5361

e-mail:

•

LSIS Tokyo Office _ Tokyo, Japan

Tel: 81-3-3582-9128

Fax: 81-3-3582-2667

e-mail:

•

LSIS Shanghai Office _ Shanghai, China

Tel: 86-21-5237-9977(609) Fax: 89-21-5237-7189 e-mail:

•

LSIS Beijing Office _ Beijing, China

Tel: 86-10-5825-6027(666) Fax: 86-10-5825-6028 e-mail:

•

LSIS Guangzhou Office _ Guangzhou, China

Tel: 86-20-8328-6754

Fax: 86-20-8326-6287 e-mail:

•

LSIS Chengdu Office _ Chengdu, China

Tel: 86-20-8328-6754

Fax: 86-20-8326-6287 e-mail:

•

LSIS Qingdao Office _ Qingdao, China

Tel: 86-532-8501-6068

Fax: 86-532-8501-6057 e-mail:

•

LSIS Europe B.V., Netherlands

Tel: +31 (0)20 654 1420

Fax: +31(0)20 654 1429 e-mail:

•

Homepage:

LS constantly endeavors to improve our products so that information in this

datasheet is subject to change without notice

.

The date of issue: 2013. 11

10310000448 Ver 3.2

GPL-TR2B

GPL-TR4B

GPL-DT4B

GPL-D22C

GPL-D24C

GPL-DT4C

GPL-TR2C

GPL-TR4C

GPL-RY2C

LS Programmable Logic Controller

Pnet(Profibus-DP) I/F Module

DATA SHEET

- When using LSIS equipment, thoroughly read this

datasheet and associated manuals introduced in this

datasheet. Also pay careful attention to safety and handle

the module properly.

- Store this datasheet in a safe place so that you can take it

out and read it whenever necessary.

Smart I/O

Caution

►

Be sure to check the rated voltage and terminal arrangement for the

module before wiring work.

Risk of electric shock, fire and malfunction.

►

Tighten the screw of terminal block with the specified torque range.

If the terminal screw is loose, it can cause fire and electric shock.

►

Use the PLC in an environment that meets the general

specifications contained in this datasheet.

Risk of electrical shock, fire, erroneous operation and deterioration of the

PLC.

►

Be sure that external load does not exceed the rating of output

module.

Risk of fire and erroneous operation.

►

Do not use the PLC in the environment of direct vibration

Risk of electrical shock, fire and erroneous operation.

►

Do not disassemble, repair or modify the PLC.

Risk of electrical shock, fire and erroneous operation

►

When disposing of PLC and battery, treat it as industrial waste.

Risk of poisonous pollution or explosion.

Precautions for use

►

Do not Install other places except PLC controlled place.

►

Make sure that the FG terminal is grounded with class 3 grounding which is

dedicated to the PLC. Otherwise, it can cause disorder or malfunction of PLC

►

Connect expansion connector correctly when expansion module is needed.

►

Do not detach PCB from the case of the module and do not modify the module.

►

Turn off power when attaching or detaching module.

►

Cellular phone or walkie-talkie should be farther than 30cm from the PLC.

►

Input signal and communication line should be farther than 10cm from a high-

tension and a power line in order not to be affected by noise and magnetic field.

A) Best

B) Good

C) Bad

Others

PLC

Others

PLC

PLC

Others

Safety Precautions

►

Safety Precautions is for using the product safely and correctly in order to prevent

the accidents and danger, so please go by them.

►

The precautions explained here only apply to this module. For safety precautions

on the PLC system, refer to User’s manual.

►

The precautions are divided into 2 sections, ‘Warning’ and ‘Caution’. Each of the

meanings is represented as follows.

If you violate instructions, it can cause death, fatal injury or a

considerable loss of property

If you violate instructions, it can cause a slight injury or a slight

loss of products

►

The symbols which are indicated in the PLC and User’s Manual mean as follows.

This symbol means paying attention because of danger of injury, fire,

or malfunction

►

This symbol means paying attention because of danger of electric shock.

Store this datasheet in a safe place so that you can take it out and read

it whenever necessary. Always forward it to the end user

Handing Precautions

►

Don’t drop or make impact.

►

Don’t detach PCB from case. It may cause problem.

►

When wiring, let no foreign material go into the module. If it goes into the module,

remove it.

►

Don’t detach the module from slot while power is on

Warning

►

Do not contact the terminals while the power is applied.

Risk of electric shock and malfunction.

►

Protect the product from being gone into by foreign metallic matter.

Risk of fire, electric shock and malfunction.

►

Risk of fire, electric shock and malfunction.

Risk of injury and fire by explosion and ignition.

Warning

Caution

Summary of Contents for Smart I/O

Page 2: ......