PROPELLER UPBLAST IO&M

B51071-005

2

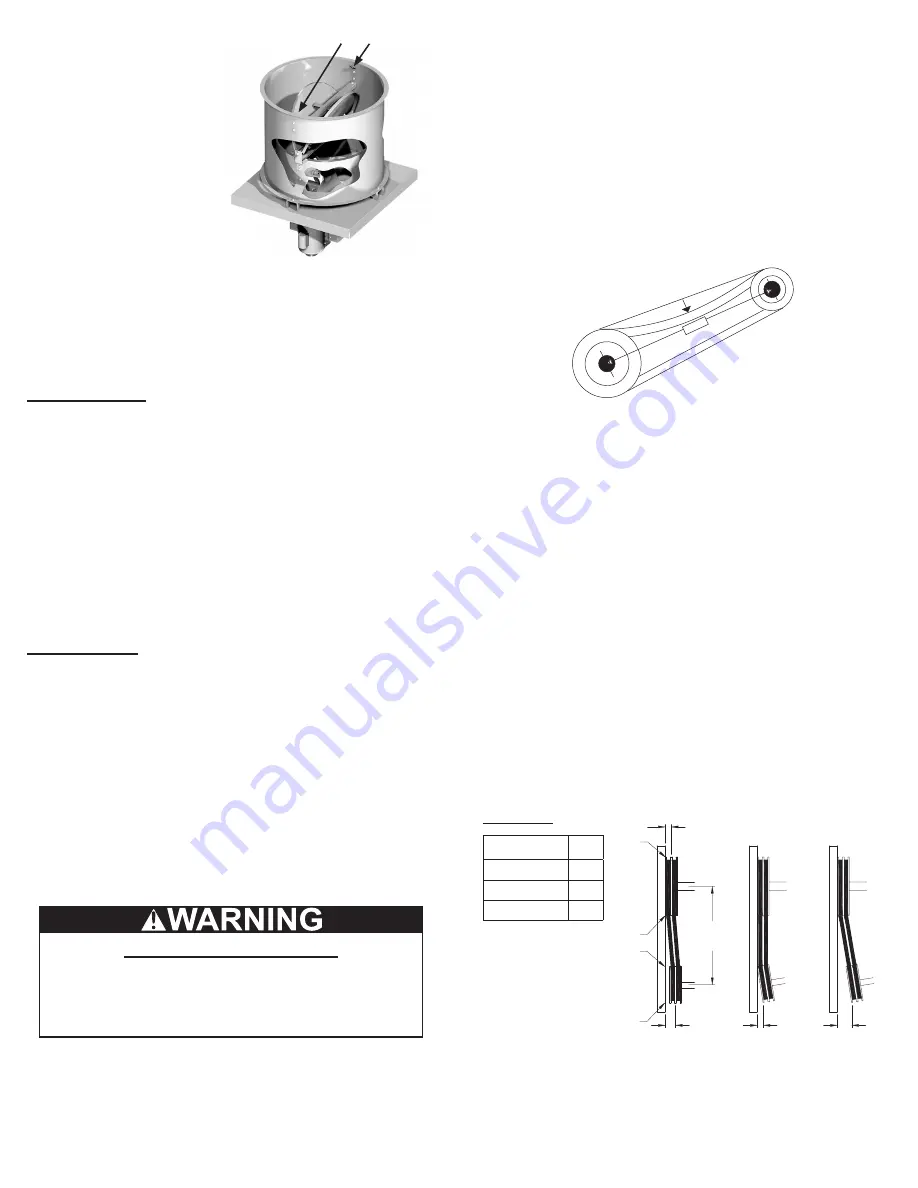

Handling

Lift propeller roof ventila-

tors by lifting lugs located in-

side the wind band. Never lift

by the shaft, motor, propeller,

or coupling. If your fan has a

special protective finish, han

-

dle with extreme care. Even

a small chip will break the

coating’s continuity and de-

stroy its ability to protect the

metal. Propellers are carefully

balanced to give smooth, vibration

free operation. If the propeller is dam-

aged during handling, it will require re-balancing.

Storage

If the fan is stored for any length of time prior to installation,

store it in its original shipping crate and protect it from dust,

debris and the weather.

Outdoor Storage

To maintain good working condition of the fan when it is

stored outdoors or at a construction site, follow the additional

instructions below.

• Coat the shaft and bearings with grease or rust preventative

compound to help seal out moisture

• Periodically rotate the propeller and operate the dampers (if

supplied) to keep a coating of grease on all internal bearing

parts

• Periodically inspect the fan to prevent damaging conditions

• Block propeller to prevent natural rotation

• Cover the unit with some type of weather cover to prevent

moisture, corrosion, dirt or dust accumulation

Installation

Damper Installation

1. Place the damper inside the curb. Ensure the damper will

open freely for the correct direction of the airflow.

2. Secure to curb at the damper shelf by installing at least

two sheet metal screws (#10 x 1/2”) on each side of the

damper, through the tray, with the screw head catching

the flange on the damper. This will prevent the dampers

from lifting.

3. Drill a hole in the curb shelf for conduit needed for motor

wiring.

4. Operate the dampers manually to ensure the blades move

freely. Dampers should be released from full open posi-

tion to check for proper closing.

Safety Recommendation

An inlet guard is recommended. An inlet guard prevents

any large debris from being pulled into the fan and damag-

ing the propeller. The inlet guard is installed on top of the

curb prior to the installation of the fan.

Motor Installation

To prevent damage to the fan during shipping, motors 5HP

and larger and extremely heavy motors (cast iron or severe

duty) are shipped loose and must be field mounted.

The motor should be mounted so that the motor plate is

between the fan shaft and motor shaft.

• Remove the motor plate mounting bolts and the motor plate

• Remove the motor mounting bolts from the motor plate

• Mount the motor to the motor plate aligning to the appropri-

ate holes

• Place the motor plate on the power assembly and rein-stall

the mounting bolts

Figure 1

1

foot

1/4

inch

Belt and Pulley Installation

If your fan is a direct drive (models AI, AUD, EUD and TUD),

proceed to

Wiring Installation

.

Belt tension is determined by the sound of the belts when

the fan is first started. The belts will produce a loud squeal,

which dissipates after the fan is operating at full capacity. If

belt tension is too tight or too loose, lost efficiency and dam

-

age can occur.

Do not change the pulley pitch diameter to change tension.

The change will result in a different fan speed.

• Loosen the motor plate adjustment nuts on motor base and

move motor plate in order that the belts can easily slip into

the grooves on the pulleys. Never pry, roll or force the belts

over the rim of the pulley

• Adjust the motor plate until proper tension is reached. For

proper tension, a deflection of approximately 1/4” per foot of

center distance should be obtained by firmly pressing the

belt. Refer to

Figure 1

• Lock the motor plate adjustment nuts in place

• Ensure pulleys are properly aligned. Refer to

Figure 2

Tolerance

Center

Distance

Max.

Gap

Up through 12” 1/16”

12” through 48 1/8”

Over 48

1/4”

OFFSET

ANGULAR

OFFSET/ANGULAR

A

W

X

Y

Z

B

CENTER

DISTANCE

(CD)

GAP

GAP

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pulley set-

screw and by moving the motor pulley on the motor shaft.

Figure 2

indicates where to measure the allowable gap for

the drive alignment tolerance. All contact points (indicated by

WXYZ) are to have a gap less than the tolerance shown in the

Lifting Lugs

Figure 2