User Manual

LogicS-2 / LogicS-3

Page 20/33

4.2.5. Activation of the End Position Alignment Procedure

Activating the end position alignment procedure lies within the scope of initial

operation carried out by a service technician.

Note:

Whether the "S7" function is available or not depends on the

configuration of the control box.

1.

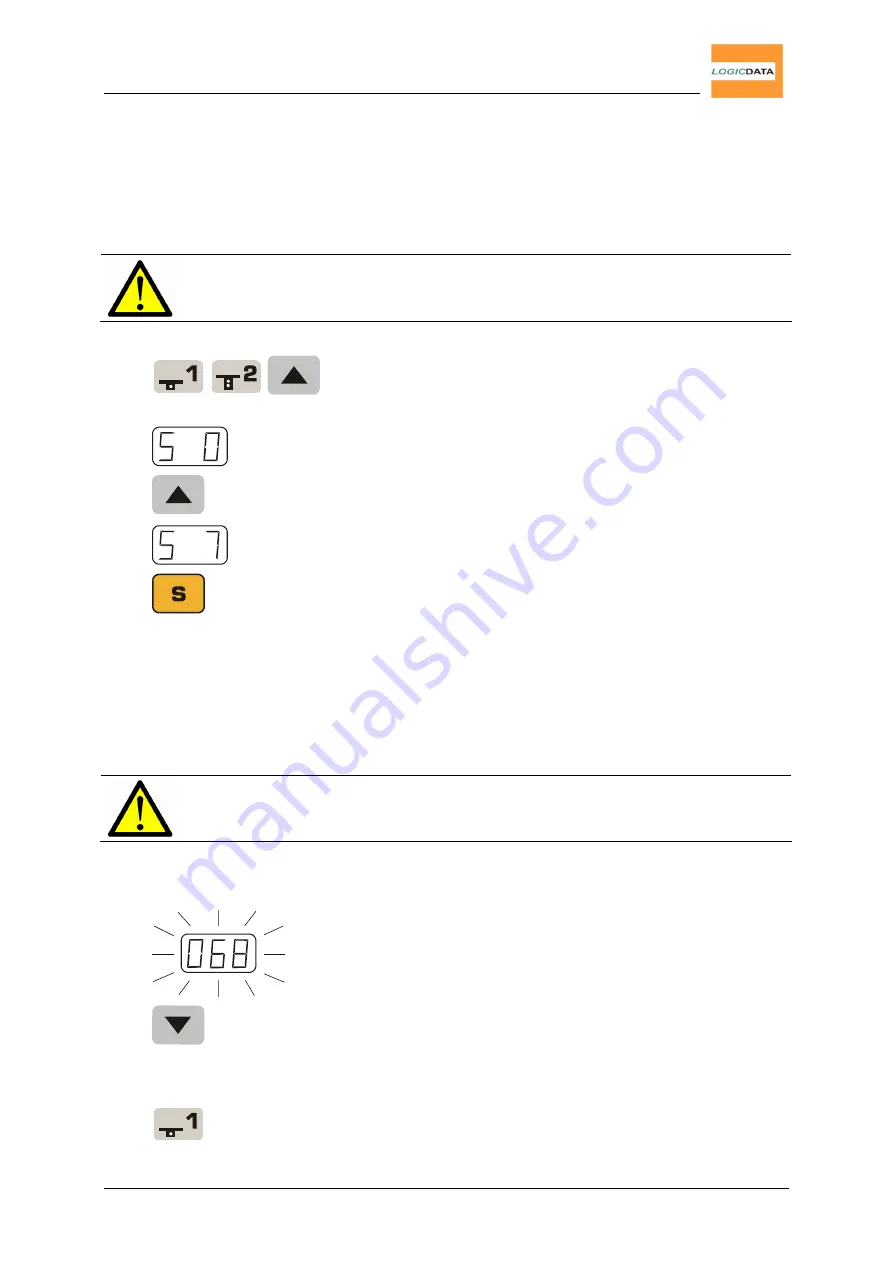

Press keys T1, T2 and desk up simultaneously.

Keep holding this key combination for about 10

seconds. Release the keys.

The display reads S 0.

2.

Press and hold key desk up until the display reads

S 7.

The display reads S 7.

3.

Press the S key.

4.2.6. End Position Alignment

The end position alignment procedure has to be carried out on initial operation

after the control box has been installed correctly.

Note:

Selectively, all configurations needed for initial operation can be

factory-made.

To align the end positions, proceed as follows:

1.

068 is flashing on the display.

2.

Press and hold key desk down until the desk has

reached the lower end position.

3.

Adjust the display according to the actual height of

the desk.

Press key T1 to increase the displayed height

(driving in any direction is locked).