Owner’s Manual (Snowblower)

N14821 2 - September, 2002

3

Set-up and Operating Instructions Continued

Operating:

8.

Check to make sure that all shields are in place

and secure.

The Loftness snowblower is an effective, reliable

machine used for the removal of snow. Before

operating this machine, become familiar with and

study all the hazard warning and safety precautions

listed in this book.

CAUTION:

Become familiar and know how to use all safety

devices and controls on the snowblower

before attempting to operate the unit. Know how to

stop the unit before starting it.

WARNING:

Read and observe all warnings on the machine

before attempting to operate the snowblower.

Do not attempt to operate this machine unless all

factory installed safety devices are in place.

CAUTION:

Before proceeding to perform any adjustments on

The snowblower, exercise the “Mandatory Shut-

down Procedure” (see section 1, page 1-2).

•

The chain and sprockets should be inspected

should be inspected for alignment and tension

on the initial use, and a periodic check should

be made to keep them in alignment.

•

Adjust the chain idler and re-tighten after one

(1) hour of use. Chain should have about one

inch of deflection.

WARNING:

Keep all guards, shields, and

decals in place.

•

The gearboxes use SAE #90 gear oil and should

be checked regularly. Warranty will not be

allowed when it is evident that gears were run

dry.

•

Operator should not raise and lower blower

under heavy loads to gain traction.

•

Adjust the blower skid shoes so the cutting

blade is about 1/2” above the ground for best

results.

•

Do not use the snowblower as a bulldozer to

push snow, let the blower work its way through

the snow.

•

Wet sticky snow requires more power to blow.

The snowblower works better in this type of

snow if it is kept working at its full capacity.

•

Best operating speeds of fan depend on snow

conditions.

•

Do not use your hands or feet to unplug the

chute. Do not attempt to clear a plugged chute

while the snowblower is under power.

Disengage the PTO or hydraulic controls by

shutting off the power unit, remove ignition key,

wait for all movement to stop, and then clear the

snow from the chute using a wooden pole.

A definite pattern of operation is required to

thoroughly clean the snow area. The patterns shown

below will avoid throwing snow in unwanted places

as well as eliminating a second removal of snow.

Diagram “A” illustrates the removal of sow when it

is possible to throw the snow to the left and right, as

on a long driveway. Start in the middle and work

towards the opposite ends, throwing the snow to

both sides without changing the direction of the

discharge chute.

Diagram “A”

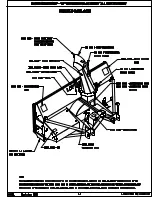

Summary of Contents for 842S

Page 5: ...Section 1 Safety ...

Page 12: ......

Page 13: ...Section 2 Operating ...

Page 19: ...Section 3 Maintenance ...

Page 20: ......

Page 26: ......

Page 27: ...Section 4 Service Parts ...

Page 28: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......