11

REPLACE THE TANK’S FILLER/BREATHER…YEARLY

There is a media inside this breather that will trap-out

airborne dirt. This inexpensive unit is a “throwaway”

part, don’t bother trying to clean it…just get a new one

from LOADMASTER and replace it. This breather is also

your oil fill neck and has a wire basket to stop big stuff

from falling into the tank when opened.

12

REPLACE THE HYDRAULIC FLUID…ONCE EVERY

OTHER YEAR

This would be the minimum change-out frequency. A

yearly change-out would be better. Modern hydraulic

fluids have additive and lubricity packages that will

deplete and wear down overtime. Always replace your

hydraulic fluid when you are doing a “pump change-out”

(along with a new return filter and suction filter).

Replace your hydraulic fluid if you had a “contamination

experience” such as a seized valve spool or if it has a

milky (water contaminated) appearance.

13

PRESSURE WASH THE UNIT TO REDUCE FIRE

RISK…WEEKLY

Well, at least once a month. Allowing any hydraulic fluid

to accumulate will make putting out any fires much

more difficult and also be a possible fire origin spot. A

clean LEGACY3 tends to be a better-maintained and

safer LEGACY3.

14

GREASE

THE

CONTROL

RODS

PLASTIC

BEARINGS…WEEKLY

If a lot of mechanical drag exists in the controls for the

valves that have the knockout positioners, it may cause

them to operate erratically. A regular greasing also

forces out (displaces) moisture that can attack the steel

shafting (corroding and pitting), thereby causing even

more drag. Sometimes, what is thought to be a

hydraulics problem is really a mechanical control

problem.

[Sec02-pg13]

Summary of Contents for LEGACY 3 Series

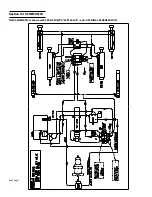

Page 13: ...Sec02 pg04 1 2 3 5 6 6 7 9 17 16 18 20 21 8 11 15 19...

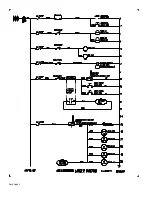

Page 17: ...Sec02 pg08 1 5 8 7 9 6 13...

Page 19: ...sec02 pg10 1 2 3 4 9 10 12 14...

Page 25: ...Sec03 pg02...