Instruction Manual

10

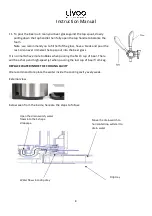

TO CHANGE BEER TUBE

Please replace the beer tube if it is damaged and causes beer leakage.

1.

Remove the cap by pressing the switch below the throat clamp.

2.

Pulling down the tap handle until it is full open and keep it opened this way.

3.

Draw out the tube from the tap and pull down the connection and tube.

4.

Replace the tube by a new beer tube and install the beer tube according to above steps, in reverse

procedure.

NOTES: Do not move other screws when processing tube replacement, otherwise, it may cause the beer leakage or

gas leakage.

MAINTENANCE

You can check the Troubleshooting Guide. It gathers causes of minor operation problems that you can

correct by yourself.

Trouble

Cause

Troubleshooting

The tap does not

work / can’t pour

beer out

1. The pouring tube is not well set in the

adaptor

2. No beer in the keg

1. Check and connect the tube to the adaptor

2. Change a new keg

Too much foam

pouring out

1. Use a wrong way to pour beer out

2. The beer temp is high (better at 3-5°C)

3. The keg is shaken before usage

4. Almost no beer in the keg

1. Use the right way to pour beer out

2. Cool the beer down to 3-5°C

3. Put the beer keg aside a while until no

bubble inside

4. Change a new keg

Beer flows out too

slowly

1. There's not much beer left. There's low air

pressure in the barrel

1. Change a new keg