2

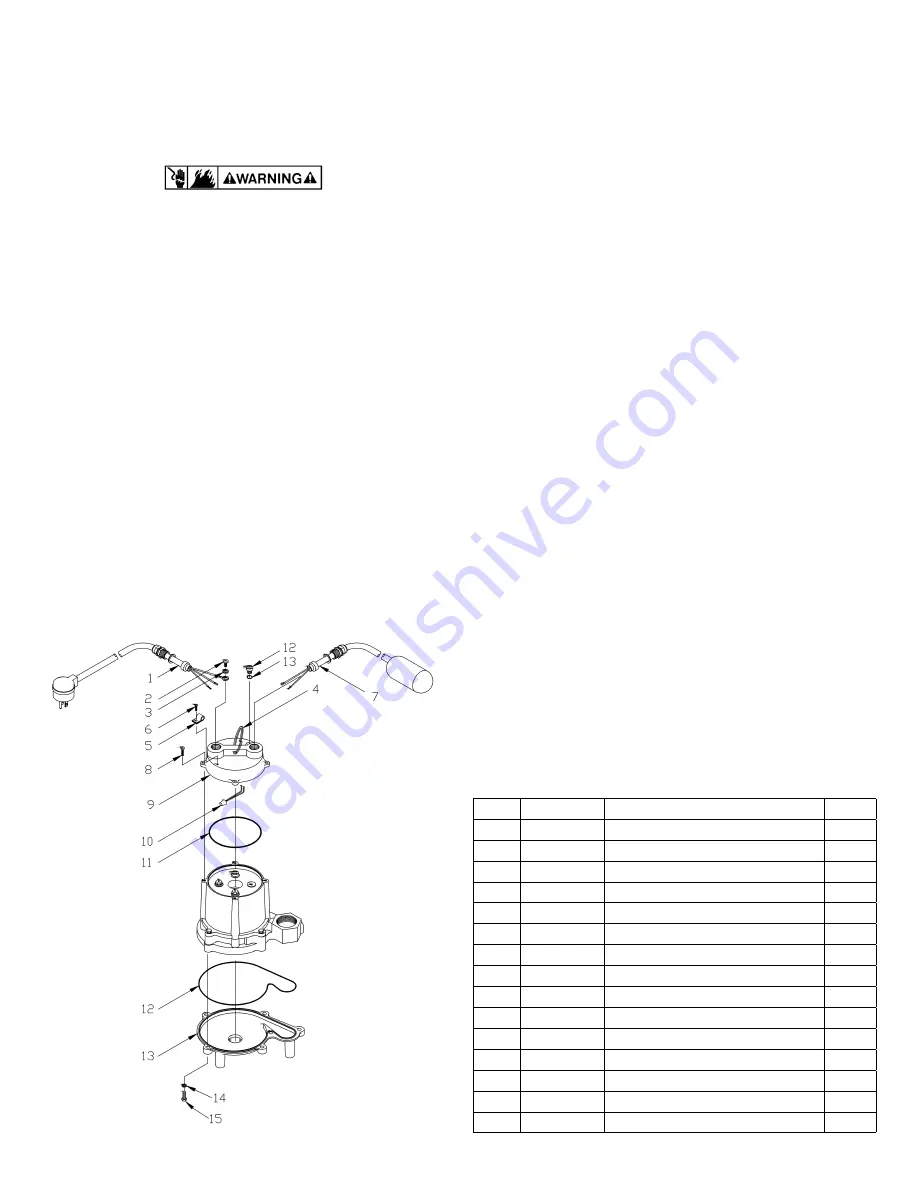

ITEM

PART NO.

DESCRIPTION

QTY.

1

951600

Wiring Harness, 15’

1

2

902437

Screw, #8-32 x 1/4

1

3

921059

Washer, Lock, #8

1

4

114100

Handle, Wire

1

5

927027

Clamp, Loop

1

6

901424

Screw, #8-32 x 1/2

1

7

950225

Switch Assembly

1

8

909022

Screw/Washer, #10-24 x 5/8

4

9

106669

Cover, Automatic

1

10

950400

Wire Nut, 14-18 AWG

1

11

928008

Seal Ring, 4.718 x .078

1

12

928040

Seal Ring, 7.928 x .063

1

13

106378

Screen/Base

1

14

921103

Washer, Lock, 1/4

6

15

903725

Screw, Cap, 1/4-20 x 7/8

6

REPLACEMENT PARTS

7. The flexible PVC jacketed cord assembly mounted to the

pump must not be modified in any way, with the exception

of shortening the cord to fit into a control panel. Any splice

between the pump and the control panel must be made within a

junction box and mounted outside of the basin and comply with

the National Electrical Code.

OPERATION

1. Pump should be installed in a suitable basin which is at least 18”

in diameter and 24” deep, in accordance with local plumbing

codes.

2. When a pump is in a basin, etc. do not touch motor, pipes or

water until unit is unplugged. If your installation has water or

moisture present, do not touch wet area until all power has been

turned off.

3. Pump features a 1-1/2“ female NPT discharge.

4. Pump must be placed on a hard level surface. Never place

pump directly on clay, earth or gravel surfaces.

5. A check valve must be used in the discharge line to prevent

back flow of liquid into the basin. The check valve should be a

free flow valve that will easily pass solids.

CAUTION: For best performance of check valves, when handling

solids install in a horizontal position or at an angle of no more

than 45 degrees. Do not install check valve in a vertical position

as solids may settle in valve and prevent opening on start-up.

6. Do not attempt to restrict the intake side of these pumps.

Restricting the intake may cause damage to the seal and may

starve the pump. If you require reduced flow rates, then place a

valve on the discharge side of the pump or if flexible vinyl tubing

is used, a clamp can be used on the tubing to restrict the flow.

7. Do not let the unit operate dry. It is designed to be cooled by

pumping fluid. You may damage the seal and the motor may fail

if the pump is allowed to run dry.

8. If the unit is going to be idle for a period of time, follow the

cleaning instructions outlined in the next section. Do not let

the unit freeze in the wintertime. This may cause cracking or

distortion that may destroy the unit.

TESTING PUMP OPERATION

NOTE:

BE CERTAIN PUMP IS SECURE IN BASIN AND FLOAT MOVES

UNOBSTRUCTED WITHOUT TOUCHING THE BASIN WALLS OR

PLUMBING.

1. These pumps are equipped with a float operated switch. When

these pumps are installed in a basin with a sealed cover, switch

operation cannot be observed. The sump cover usually will have

a spare hole that is plugged with a rubber plug. This plug can be

removed and switch operation can be observed.

2. Plug power cord into a grounded receptacle with voltage

consistent with pump voltage as indicated on pump nameplate.

3. Run water into basin until pump starts.

4. Be sure gate valve in discharge line is open.

5. Allow pump to operate through several on-off cycles.

6. If pump does not operate properly, consult the Troubleshooting

table. If trouble cannot be located with these steps shown,

consult your pump dealer or take pump to a Little Giant

authorized service center.

Figure 2.