36

GAMMA SERIES ENGINES OpERATORS' hANdbOOk

28

GAMMA SERIES ENGINES OPERATORS' HANDBOOK

1.Place a tray under the filter to collect

spilt lubricating oil.

2.Remove the filter canister with a strap

wrench or similar tool. Ensure that

the adaptor

(Figure 5.10)

is secure

in the filter head, and then discard

the canister.

3.Clean the filter head .

4.Add clean lubricating oil to the new

canister. Allow the oil enough time to

pass through the filter element.

5.Lubricate the top of the canister seal

with clean lubricating oil.

6 .Fit the new canister and tighten it

by hand only. Do

NOT

use a strap

wrench.

7. Ensure that there is lubricating oil in

the sump. On turbocharged engines,

ensure that the engine will not start

and operate the starter motor until oil

pressure is obtained. To ensure that

the engine will not start, either put

the manual stop control in the

stop

position or disconnect the electrical

stop control of the fuel injection

pump. Oil pressure is indicated when

the warning light is extinguished or

by reading a gauge.

8.Operate the engine and check for

leakage from the filter. When the

engine has cooled, check the oil level

on the dipstick and put more oil into

the sump if necessary.

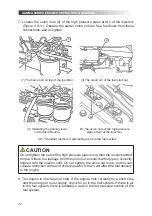

5.11 CLEANING THE

BREATHER SYSTEM

Refer to

Figure 5.11

.

1.Release the hose clip and remove

the breather cover (1).

Note:

It is necessary to remove the breather

body in the rocker cover so that a strainer

can be put into it.

2.Remove the plastic strainer (2) and

wash it with clean kerosene.

3.Wash the breather body with clean

kerosene.

4.lf necessary, renew the O-ring (3).

Figure 5.11 Cleaning the breather system. (1)

breather cover; (2) plastic strainer; (3) O-ring.

5.Check that the inside of the upper

pipe is clean. If the pipe is not clean,

release the flange setscrews and

remove the pipe. Wash the pipe with

kerosene and dry with low pressure air.

6.Fit the breather cover onto the body

and ensure that it is fitted firmly.

7.Fit the upper pipe and tighten the

hose clip.

Note:

The breather body is fixed on the

cover with screws. If it is necessary to

remove the breather assembly, use a

spanner to clamp the flange on the bottom

before loosening the screws.

5.12 SERVICING THE AIR

CLEANER

A typical wet -type air cleaner is shown

in

Figure 5.12

. The wet type air cleaner

must be drained regularly.

1.The container and element (1) must

be cleaned with kerosene or with

another suitable fluid . Do

NOT

use

gasoline.

2.Check that the seal (2) is not

damaged. Renew it if necessary.

3.Fill to the indicated level (3) with

clean engine lubricating oil.

Figure 5.11 Cleaning the breather system. (1) breather cover; (2) plastic strainer; (3) O-ring

5. Check that the inside of the upper pipe is clean. If the pipe is not clean, release

the flange setscrews and remove the pipe. Wash the pipe with kerosene and

dry with low pressure air.

6. Fit the breather cover onto the body and ensure that it is fitted firmly.

7. Fit the upper pipe and tighten the hose clip.

Note:

The breather body is fixed on the cover with screws. If it is necessary to remove the

breather assembly, use a spanner to clamp the flange on the bottom before loosening the

screws.

5.12 SERvICING ThE AIR ClEANER

A typical wet type air cleaner is shown in

Figure 5.12.

The wet type air cleaner

must be drained regularly.

1. The container and element (1) must be cleaned with kerosene or with another

suitable fluid. Do

NOT

use gasoline.

2. Check that the seal (2) is not damaged. Renew it if necessary.

3. Fill to the indicated level (3) with clean engine lubricating oil.

29

GAMMA SERIES ENGINES OPERATORS' HANDBOOK

Figure 5.12 A typical wet type air cleaner.

5.12.1 Air Filter

Environmental conditions have an

important effect on the frequency at

which the air filter needs service

Refer to

Figure 5.12.1

.

Figure 5.12.1 The air filter, showing the

dust bowl (1) and element (2).

Certain air filters have a separate dust

bowl (1) which must be cleaned at

intervals. Do not let dust completely

fill the bowl as this will reduce the life

of the filter element (2). The amount

of dust in the bowl indicates whether

it has been removed early enough for

the conditions of operation.

Certain air filters have automatic dust

valves through which dust is expelled

from the filter

(Figure 5.12.2)

. The

rubber dust valve (1) must be kept

clean. Ensure that the sides of the

valves close completely together and

that they can separate freely.

Figure 5.12.2 Air filter with dust valve (1).

If a restriction indicator is fitted (see

below) it will indicate precisely when the

air filter element needs servicing. This

prevents the premature removal of the

filter, which is an unnecessary expense,

or late removal which can cause loss

of power. The filter element must be

cleaned or renewed according to the

manufacturer's recommendations.

5.12.2 Restriction Indicator

The restriction indicator for these

engines must work at a pressure

difference of 508/558mm (20/22 in) of

water gauge.

It is fitted on the outlet pipe of the air

cleaner.

Refer to

Figure 5.12.3

. When the red

warning light (1) is seen through the

clear panel (2) after the engine has

stopped, the air filter element must be

Figure 5.12 A typical wet type air cleaner.

Summary of Contents for GW3

Page 59: ...59 ...