Rev: 06.30.22

Page 14

CCD-0001575

Maintenance

The bed lift system requires very little maintenance. The chains are pre-lubricated and nickel-plated to

prevent corrosion. All bearings are sealed and all parts are either plated or finished with a durable powder-

coat finish.

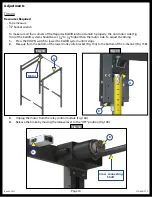

The only required maintenance involves keeping the mechanisms clean and free of debris. When cleaning

the trailer after use, inspect the vertical trolley channels for dirt or debris and clean as necessary. After

cleaning, a light application of dry silicone spray on the inner sides of the trolley channels will improve

performance and reduce noise and required amperage draw.

Troubleshooting

What Is Happening?

Why?

What Should Be Done?

Bed(s) will not move

either up or down

when switch is pressed.

No or insufficient power to

operate the bed(s).

Make certain trailer batteries are adequately

charged, connect to shore power or a generator.

Faulty control module.

Replace module.

Faulty UP/DOWN switch.

Replace switch.

Defective motor.

Contact Lippert Customer Service.

Bed travels in only

one direction.

Defective limit switch.

Replace limit switch.

Faulty control module.

Replace module.

Faulty UP/DOWN switch.

Replace switch.

Faulty brake.

Set manual brake release lever on motor to

the "OFF" position. If the bed(s) move, replace

the faulty brake.

Bed lowers, but stops

part way going up.

Insufficient power to bed.

Make certain trailer batteries are adequately

charged, connect to shore power or a generator.

Defective motor/brake assembly.

Contact Lippert Customer Service.

Bed does not stay level;

side-to-side or front-to-

back.

Broken or loose timing shaft.

Contact Lippert Customer Service.

Broken chain sprocket.

Contact Lippert Customer Service.

When lowered, bed

fails to stop at preset

stop point.

Motor brake not engaging.

Contact Lippert Customer Service.

Defective limit switch.

Replace limit switch.

When raised, bed fails to

stop at preset stop point.

Defect or damaged limit

switch.

Replace limit switch.

Upper bunk (two-bed

system) does not

lower smoothly.

Sticky bed carrier.

Spray a small amount of dry silicone

lubricant into the rails.

Bed(s) are drifting

down.

Brake lever is off

Reset the brake lever.

Motor failures are extremely rare and motors are expensive. If uncertain of failure, contact Lippert customer