2

dc1759af

DEMO MANUAL DC1759A

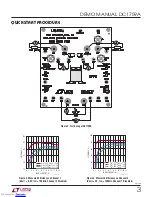

QUICK START PROCEDURE

Demonstration circuit 1759A is easy to set up to evalu-

ate the performance of the LTM4620AEV. Please refer to

Figure 2 for proper measurement setup and follow the

procedure below:

1. Place jumpers in the following positions for a typical

application:

JP1

JP2

JP3

JP4

JP5

JP6

MODE

RUN1

RUN2

TRACK1

SEL.

TRACK2

SEL.

CLKOUT

PHASE

CCM

ON

ON

SOFT-

START

SOFT-

START

90°

2. With power off, connect the input power supply, load

and meters as shown in Figure 2. Preset the load to 0A

and V

IN

supply to 12V.

3. Turn on the power supply at the input. The output

voltage in channel 1 should be 3.3V ±1.5% (3.2505V

~ 3.3495V) and the output voltage in channel 2 should

be 5V ±1.5% (4.925V ~ 5.075V).

4. Once the proper output voltage is established, adjust the

load within the operating range and observe the output

voltage regulation, output voltage ripple, efficiency and

other parameters. Output ripple should be measured

at J1 and J2 with BNC cables. 50Ω termination should

be set on the oscilloscope or BNC cables.

5. (Optional) For optional load transient test, apply an

adjustable pulse signal between IOSTEP CLK and GND

test point. Pulse amplitude (3V ~ 3.5V) sets the load

step current amplitude. The output transient current

can be monitored at the BNC connector J3 (15mV/A).

The pulse signal should have very small duty cycle

(<1%) to limit the thermal stress on the transient load

circuit. Switch the jumper resistors R34 or R35 (on the

backside of boards) to apply load transient on channel 1

or channel 2 correspondingly.

6. (Optional) LTM4620A can be synchronized to an external

clock signal. Place the JP1 jumper on EXT_CLK and

apply a clock signal (0V ~ 5V, square wave) on the

CLKIN test point.

7. (Optional) The outputs of LTM4620A can track another

supply. The jumpers JP4 and JP5 allow choosing soft-

start or output tracking. If tracking external voltage is

selected, the corresponding test points, TRACK1 and

TRACK2, need to be connected to a valid voltage signal.

8. (Optional) LTM4620A can be configured for a 2-phase

single output at up to 26A on DC1759A. Install 0Ω

resistors on R14, R17, R28, R39 and remove R7,

R19. Output voltage is set by R25 based on equation

V

OUT

= 0.6V(1 + 60.4k/R25).

PERFORMANCE SUMMARY

PARAMETER

CONDITION

VALUE

Input Voltage Range

5.5V ~ 16V

Output Voltage V

OUT1

V

IN

= 5.5V ~ 16V, I

OUT1

= 0A ~ 13A, JP1: CCM

3.3V ±1.5%

Output Voltage V

OUT2

V

IN

= 5.5V ~16V, I

OUT2

= 0A ~ 13A, JP1: CCM

5V ±1.5%

Per-Channel Maximum Continuous Output Current

Derating is Necessary for Certain V

IN

, V

OUT

and Thermal Conditions,

See Data Sheet for Detail.

13A (per-Channel)

Default Operating Frequency

750kHz

Resistor Programmable Frequency Range

250kHz to 780kHz

External Clock Sync. Frequency Range

400kHz to 780kHz

Efficiency of Channel 1

V

IN

= 12V, V

OUT1

= 3.3V, I

OUT1

= 13A, f

SW

= 750kHz

91.7% See Figure 3

Efficiency of Channel 2

V

IN

= 12V, V

OUT2

= 5V, I

OUT2

= 13A, f

SW

= 750kHz

93.8% See Figure 4

Load Transient of Channel 1

V

IN

= 12V, V

OUT1

= 3.3V, I

SETP

= 6.5A ~ 13A

See Figure 5

Load Transient of Channel 2

V

IN

= 12V, V

OUT2

= 5V, I

SETP

= 6.5A ~ 13A

See Figure 6

(T

A

= 25°C)

Downloaded from

Downloaded from