Summary of Contents for 1633-000-EA

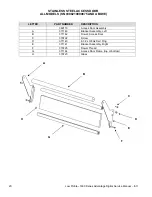

Page 19: ...Low Profile 1600 Series Advantage Digital Service Manual Int l 19 ...

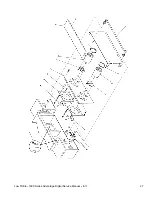

Page 23: ...Low Profile 1600 Series Advantage Digital Service Manual Int l 23 ...

Page 25: ...Low Profile 1600 Series Advantage Digital Service Manual Int l 25 ...

Page 27: ...Low Profile 1600 Series Advantage Digital Service Manual Int l 27 ...

Page 29: ...Low Profile 1600 Series Advantage Digital Service Manual Int l 29 ...

Page 32: ...Low Profile 1600 Series Advantage Digital Service Manual Int l 32 ...