800 AMP TANDEM MIG TORCH

GENERAL DESCRIPTION

The Tandem MIG 800 Amp Welding Torch is

designed to deliver two wire electrodes to a single

weld pool. The wire electrodes are electrically isolated

from one another providing independent parameter

control of both electrodes. The torch has two separate

wire spacing options. The torch is designed primarily

for robotic applications utilizing wire electrodes in the

diameters of .035 through .062 inches. Torch ratings

are based on the use of shielding gas mixtures con-

taining a minimum of 82% argon gas.

The torch is designed for easy maintenance.

The aluminum construction of the gooseneck outer

jacket and mounting /clamping assemblies defines the

lightweight low profile of the torch. The long goose-

neck design is provided for ease of robot program-

ming for access to restricted welding joints.

A single water-cooling source to circulate water

through the nozzle assembly establishes torch cool-

ing. The aluminum mounting and clamping assembly

serves as an added cooling feature providing a heat

sink to draw heat from the contact tip area and goose-

necks.

The torch may be operated as either a Tandem con-

figuration with two wire electrodes, or as a single wire

torch for special applications. Because of the size of

the Tandem MIG nozzle, during single wire operation

gas delivery through both diffusers is required.

TORCH MOUNTING

The torch mounting arm is an integral part of the torch

mounting and clamping assembly, and should not be

removed or altered. The mounting arm is designed to

place the welding arc at the center line of a robot

mounting plate for programming ease. The arm is fur-

nished with a .647" hole for inserting a S22637 torch

mounting locking wedge. The mounting wedge is

designed to secure the torch to a common .75 " diam-

eter torch collision sensor shaft.

Due to the weight of the torch and rapid movement of

many robotic applications it is recommended that a

rigid mount be used to secure the torch to a robot

arm. The rigid mount S22693-172 is to be used in

conjunction with robot collision sensing software.

NOTE:

The S22693-172 rigid mount is a dummy colli-

sion sensor. It is not designed to sense a torch colli-

sion. For proper operator and equipment protection

the S22693-172 rigid mount should only be used in

conjunction with robotic arm collision sensing soft-

ware.

For hard automation applications and for use with

robots that do not have collision sensing software, a

heavy-duty collision sensor is recommended

(M17809).

The collision sensor must be of proper rating to

withstand the high inertia stopping and starting associ-

ated with robot high-speed motion without tripping the

sensor.

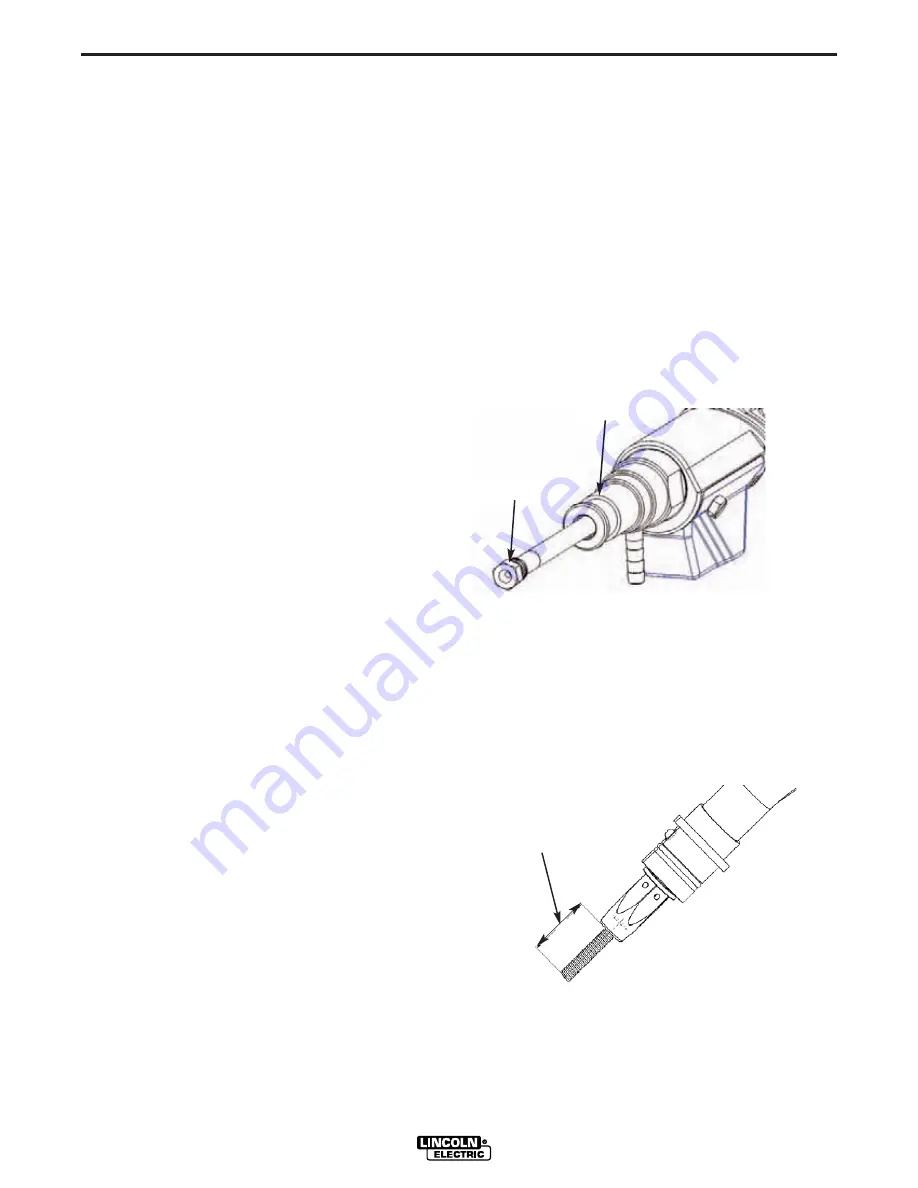

LINER INSTALLATION

1. Lay the torch and cable on a flat surface and

extend cables straight.

2. Remove contact tip and diffuser.

3. With cables straightened, loosen 3/8" liner nut

from power pin. Grip liner with pliers and slowly

remove.

4. With dry compressed air blow cable cavity free of

any accumulated dust or filings.

5. Feed replacement liner through cable assembly

using short strokes to avoid kinking. Twist liner

clockwise if necessary.

6. Seat liner retainer O-ring to inside shoulder bore

of power pin by tightening the 3/8" liner nut.

7. Replace diffusers, tighten securely.

8. With liner extending through torch body (contact

tip removed), trim liner to a 5/16" length.

9. Remove any burr from end of liner that may

obstruct wire feeding.

10. Replace contact tip and gas nozzle.

A-2

INSTALLATION

A-2

Power Pin

3/8" Liner Nut

5/16 "

Extension

Summary of Contents for TANDEM MIG 800

Page 21: ...NOTES 800 AMP TANDEM MIG TORCH ...