A-13

INSTALLATION

POWER WAVE AC/DC

A-13

MULTI-ARC SYSTEM DESCRIPTION

The following is a general description of how the

PowerWave AC/DC can be configured in a multi-arc

set-up.

Each welding arc may be driven by one machine or up

to four machines connected in parallel. The hardware

for the power source has been designed so that the

power source can either operate as a master or a

slave. A few DIP switches must be configured proper-

ly to set the machine

’

s identity. Each power source

has a rating of 500 amps average current, with a peak

current of 725 amps. So, four machines are capable

of driving 2000 amps of output current with up to 2900

amps of peak current available. Each arc must have

one power source designated as the master. If only

one machine is required for an arc, then it must be set

up as the master. The master power source controls

the AC switching for the arc. The slaves respond to

what the master wants

Due to the flexibility of the platform the configuration

may vary. A typical subarc system will consist of four

welding arcs, which require ten power sources and

one synchronous generator. Arc # 1 & #2 will be three

machines in parallel. Arc #3 & #4 will be two machines

connected in parallel (each individual machine is con-

nected to the ethernet hub).

The PC will function as the control center for the

AC/DC system as well as the user interface. The

Ethernet hub splits the Ethernet port from the PC to all

the power sources and the phase generator. The PC

will act to coordinate the welding sequence of the mul-

tiple machines.

One machine will be designated the master, with the

rest of the machines connected in parallel considered

slaves. The master can generate it's own AC frequen-

cy or it can use an external signal as a reference. An

external Phase Generator provides the means to syn-

chronize the AC wave shape between multiple arcs.

The phase angle between arcs can be adjusted to

reduce "Arc Blow" and other welding related issues.

An external phase control signal is required to keep

the separate wave shapes synchronized with each

other

An Ethernet-Gateway board can be used as the exter-

nal Phase Generator. An Ethernet-Gateway PC board

that can be configured to generate four phase signals

onto four differential I/O lines. The phase signals can

then be used to synchronize the four different arcs to

a common carrier frequency. The frequency can

range from 10 hertz to 300 hertz, with the most practi-

cal range being from 50 to 100 hertz. It may be desir-

able that sync signals 2, 3, or 4 are some multiple of

the first signal. The frequency and phase shift are

controlled by software.

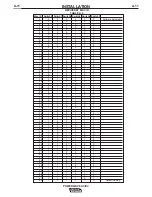

Ethernet Hub

PC

ARC

#1

ARC

#2

ARC

#3

ARC

#4

PULSE

GENERATOR

Summary of Contents for POWER WAVE AC/DC

Page 19: ...A 12 INSTALLATION POWER WAVE AC DC A 12 Bank S3 and S4...

Page 43: ...NOTES POWER WAVE AC DC...

Page 44: ...NOTES POWER WAVE AC DC...