A-3

INSTALLATION

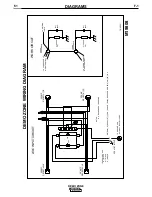

DEMO ZONE

A-3

INSTALLATION OF FIELD INSTALLED

OPTIONS

CASTER WHEELS (PART OF K1848-1)

Caster wheels, which are provided, can be installed

by lifting the Demo Zone approximately eight inches

above ground level. Use the mounting hardware sup-

plied to fasten the caster wheel to the mounting plate.

Tighten all fasteners.

INSTALLATION OF EQUIPMENT

REQUIRED FOR RECOMMENDED

PROCESSES

1. As shipped from the factory, two diagonal braces

are bolted to either side of the Demo Zone. The

braces are approximately 62" in length.

• Remove the brace on the tool box side of the Demo Zone

• Do not remove the brace located on the Ranger

250 side of the Demo Zone.

2. The Demo Zone is made for ease of set up. Drive

rolls are installed and liners are in the guns.

3. A Harris Kit, containing gas components, is includ-

ed with the Demo Zone. Some details about the kit:

• The double flow meter-regulator is for the argon

gas cylinder. A "Y" fitting is also used on one of the

flow meter outlets. The argon is fed to the Spool

Gun, The Square Wave TIG 175 and the two-piece

TIG torch attached to the Ranger 250.

• The other regulator is provided for the 75/25

argon/CO2 gas cylinder. Connect a "Y" fitting to this

regulator. The Power MIG and LN25 is fed from the

"Y" fitting. Use hoses with inert gas fittings. The

short hose is used with the LN7.

• The oxygen fitting (with 1/4 inch pipe thread) is for

use with the Pro-Cut gas hose. Use the short oxy-

gen hose between the Pro-Cut and regulator.

4. Two plasma torches are provided with the Demo

Zone. Use the short length plasma torch with the

Demo Zone. The torch with the long length is not

recommended because the length is inconvenient

when used with the Demo Zone. Store the long

plasma torch. Use the long torch if the Pro Cut is

removed from the Demo Zone.

5. BEFORE the gas cylinders are installed, run the

gun for the Power MIG from the back of the rack

through the bench (under) and then up to the

Power MIG. This gun will run along the back of the

Square Wave TIG 175 and then to a gun holder. It

should be long enough to reach the worktable and

this helps keep the cables from getting tangled.

6. BEFORE the gas cylinders are installed, measure

the cable length needed for the spool gun (it is rout-

ed the same way as the Power MIG gun) and coil

the rest, wire tie it and store it underneath the

bench between the Ranger and Power MIG.

7. BEFORE the gas cylinders are installed, connect

the battery in the Ranger 250.

8. Gas cylinder covers will improve the appearance of

your unit. When used, put the covers on before

installing the cylinder.

9. Place the cylinders in the Demo Zone. The cylin-

ders can be installed by using the rear or side

openings, or a combination of both.

When using the rear frame opening, move the upper

and lower support bars out of way. Install the cylin-

ders and replace the support bars to the closed

position.

When using side frame opening, lift brace and swing

out of the way. Install the cylinders and swing brace

back into position, push brace down through locking

tube to secure.

Place the air cylinder directly in back of the Pro Cut.

Place the argon cylinder next to the air cylinder.

10. Install the optional casters. This is easily done

after placing cylinders in Demo Zone, as the

height of the Demo Zone is higher with the wheels

installed.

11. Set up the two TIG torches provided. The TIG

torch that comes with the SW175 is used on both

AC and DC. A recommendation is to use a point at

one end of the tungsten and a ball at the other

end.

12. The welding table must exposed before demon-

strating. Pull the table to the open position when in

use. The table can be pushed back in, out of the

way, when the table is not in use. Since the table

has a bolted work lead permanently attached, no

work clamp is necessary for welding or cutting

operations.

Summary of Contents for Demo Zone

Page 19: ...NOTES DEMO ZONE...