English

10

English

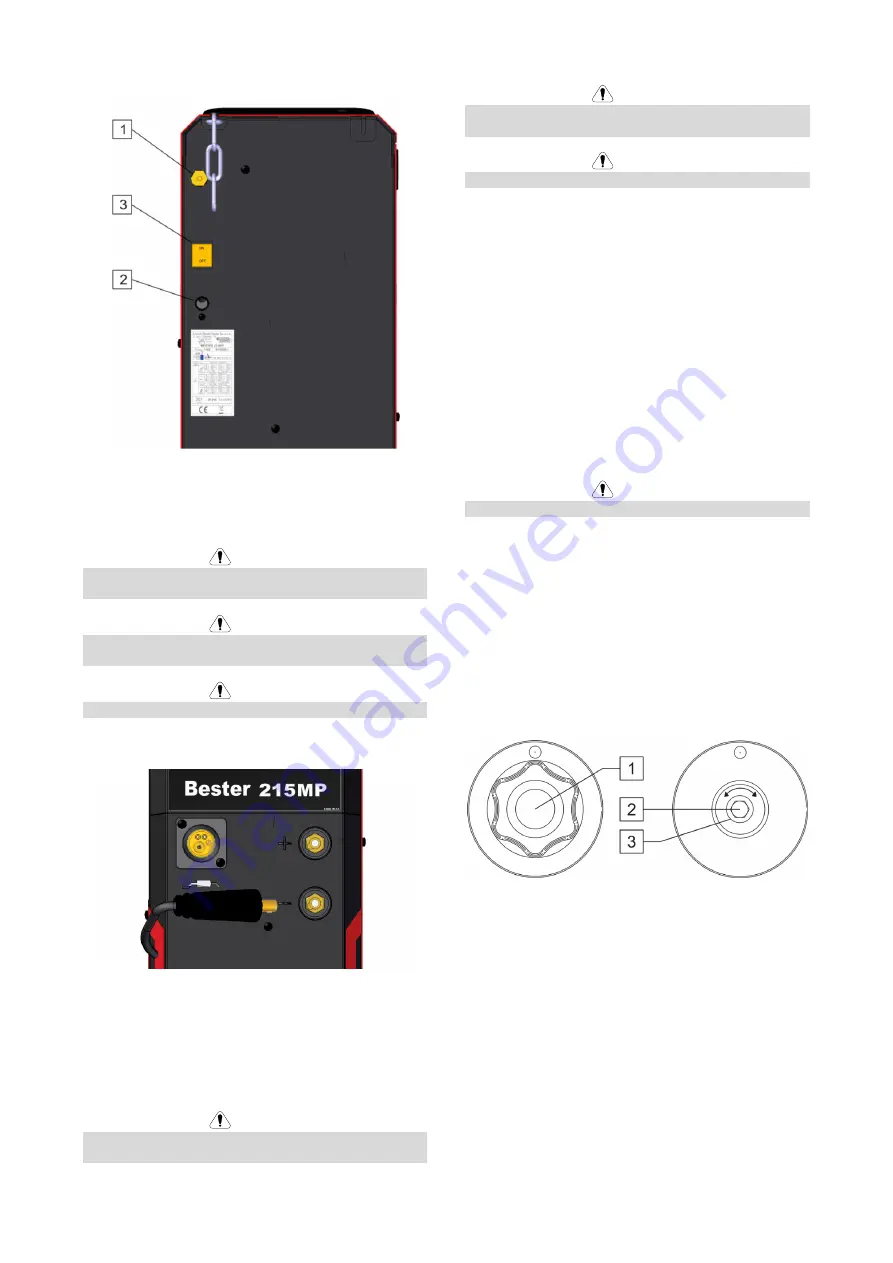

Rear Panel

Figure 3

1. Gas connector

2. Input power cord

3. Power switch

WARNING

When the machine is switched again on, last welding

process will be recalled.

WARNING

If the push-button is pushed in MIG process in, the output

terminals will lived.

WARNING

During MMA process, the output terminals are still lived.

The installation and connection

Figure 4

If the welding polarity has to be changed, user should:

•

Switch off the machine.

•

Determine the polarity for the electrode to be used

(or wire). Consult the data for this information.

•

Select and set the correct polarity: positive (terminal

8) or negative (terminal 9)

WARNING

Before welding check the polarity for using electrodes and

wires.

WARNING

The machine must be used with the door completely

closed during welding.

WARNING

Not use handle to move the machine during work.

Loading the Electrode Wire

•

Turn the machine off.

•

Open the side cover of the machine.

•

Unscrew the locking nut of the sleeve.

•

Load the spool with the wire on the sleeve such that

the spool turns anticlockwise when the wire is fed

into the wire feeder.

•

Make sure that the spool locating pin goes into the

fitting hole on the spool.

•

Screw in the fastening cap of the sleeve.

•

Put on the wire roll using the correct groove

corresponding to the wire diameter.

•

Free the end of the wire and cut off the bent end

making sure it has no burr.

•

The device is adapted to the spool max. 15 kg

300 mm

WARNING

Sharp end of the wire can hurt.

•

Rotate the wire spool anticlockwise and thread the

end of the wire into the wire feeder as far as the Euro

socket.

•

Adjust force of pressure roll of the wire feeder

properly.

Adjustments of Brake Torque of Sleeve

To avoid spontaneous unrolling of the welding wire the

sleeve is fitted with a brake.

Adjustment is carried by rotation of its Allen screw M8,

which is placed inside of the sleeve frame after

unscrewing the fastening cap of the sleeve.

Figure 5

1. Fastening cap.

2. Adjusting Allen screw M8.

3. Pressing spring.

Turning the Allen screw M8 anticlockwise increases the

spring tension and you can increase the brake torque

Turning the Allen screw M8 clockwise decreases the

spring tension and you can decrease the brake torque.

After finishing of adjustment, you should screw in the

fastening cap again.