A-2

INSTALLATION

A-2

DURAWELD

TM

350/500

SAFETY PRECAUTIONS

Read the entire installation section before starting

installation.

ELECTRIC SHOCK can kill.

Only qualified personnel

should perform this installation.

Turn the input power OFF

at the main switch or fuse box

before working on this

equipment. Turn off the input power to any other

equipment connected to the welding system at

the main switch or fuse box before working on

the equipment.

Do not touch electrically “Hot” parts.

Always connect the DURAWELD

TM

grounding lug

(located at the rear of the case) to a proper safety

(Earth) ground.

DURAWELD

TM

must only be used on three-

phase, MEN input power.

SELECT SUITABLE LOCATION

This power source should not be subjected to rain, nor

should any parts of it be submerged in water. Doing so

may cause improper operation as well as pose a safety

hazard. The best practice is to keep the machine in a

dry, sheltered area.

The bottom of machine must always be placed on a

firm, secure, level surface. There is a danger of the

machine toppling over if this precaution is not

taken.

Place the welder where clean cool air can freely

circulate in through the side and back louvers and out

through the case bottom. Water dust or any foreign

material that can be drawn into the welder should be

kept a minimum. Failure to observe these precautions

can result in excessive operating temperatures and

nuisance shutdowns.

Locate the DURAWELD

TM

machine away from radio

controlled machinery. Normal operation of the welder

may adversely affect the operation of RF controlled

equipment, which may result in bodily injury or damage

to the equipment.

INPUT POWER AND GROUNDING

CONNECTION

Only a qualified electrician should connect the

input leads to the DURAWELD

TM

. Connections

should be made in accordance with the connection

diagram. Failure to do so may result in bodily injury

or death.

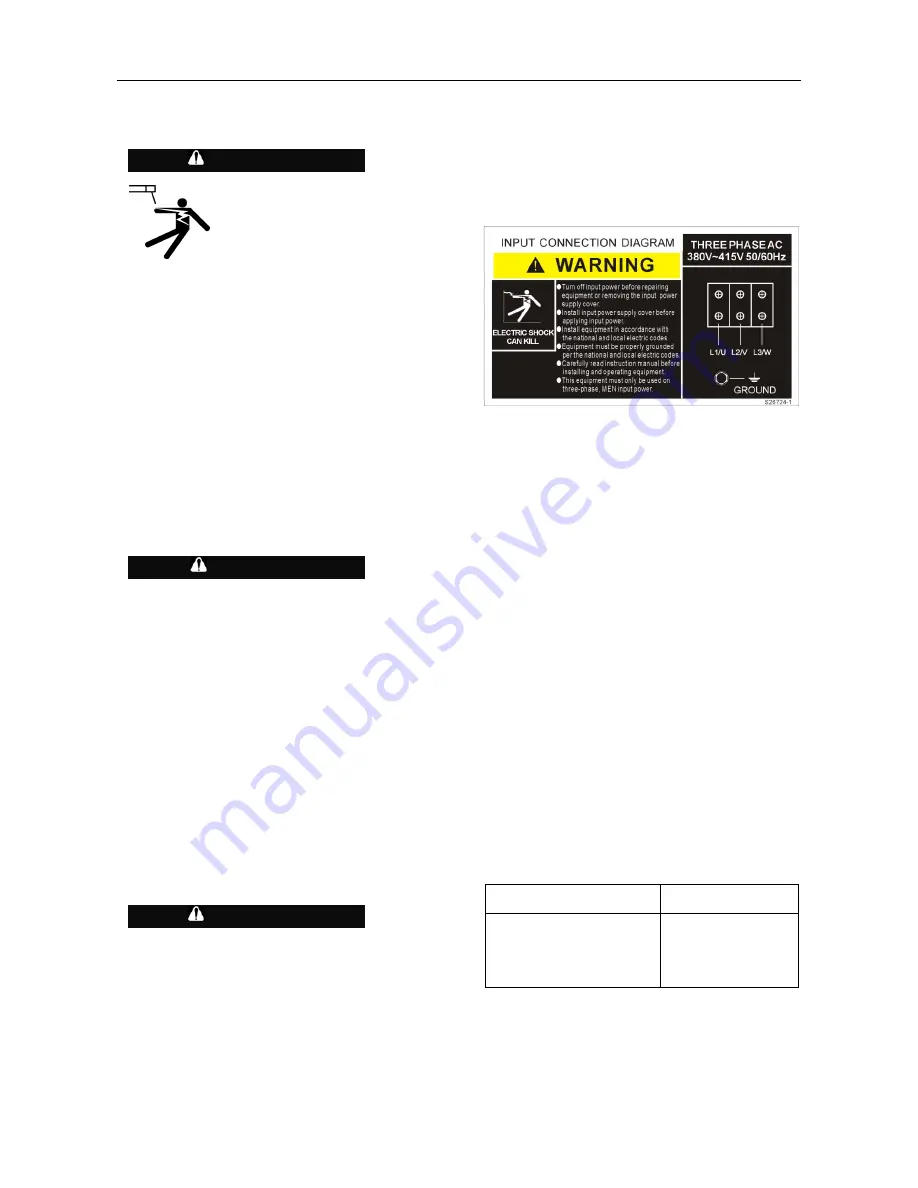

Open the input box on the rear of the case. Use a

three-phase supply line, the three live wires should go

through the three holes of the input wire holder and be

securely clamped and fixed. Connect L1, L2, L3 and

ground according to the Input Supply Connection

Diagram decal, refer to Figure A.1 on this page.

FIGURE A.1 – Input Supply Connection Diagram

The DURAWELD

TM

is supplied connected for 50Hz

input. In regions where the frequency of electricity is

60HZ, the DURAWELD

TM

machine can identify the 60

HZ frequency automatically and work in terms of this

frequency.

Make sure the amount of power available from the input

connection is adequate for normal operation of the

machine. Refer to the Technical Specifications at the

beginning of this Installation section for recommended

fuse and wire sizes. Fuse the input circuit with the

recommended super lag fuse or delay type breakers.

Using fuses or circuit breakers smaller than

recommended may result in “nuisance” shut-offs from

welder inrush currents, even if the machine is not being

used at high currents.

OUTPUT AND WIRE FEEDER

CONNECTIONS

Connect a work lead of sufficient size and length (Per

Table A.1) between the Negative Output terminal on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal electrical contact.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work and wire feeder. Avoid

excessive lengths and do not coil excess cable.

Minimum work and electrode cable sizes are as follows:

TABLE A.1

Current (60% Duty Cycle)

Minimum Copper

Work Cable Size

200A

300A

400A

500A

Up To 30m Length

30 mm

2

50 mm

2

70 mm

2

95 mm

2

Note: Recommended cable sizes may vary due to

different cable quality. The overall voltage pressure of

grounding and welding cables is no more than 4V under

rated current.

WARNING

CAUTION

WARNING