34

MUL

TI V Hydro Kit Medium T

emperature (K2) Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG Life’s Good” is a registered trademark of LG Corp.

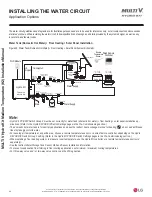

INSTALLING THE WATER CIRCUIT

Antifreeze Additives

The water circuit guidelines and diagrams are for illustrative purposes and are to be used for references only; not all components and accessories

DUHOLVWHGRUVKRZQ:KHQLQVWDOOLQJWKHZDWHUFLUFXLWIROORZVSHFL¿FDWLRQVGUDZLQJVDQGGHWDLOVSURYLGHGE\WKHV\VWHPGHVLJQHUDVZHOODVDQ\

local, state, and federal codes.

Antifreeze Additives

At locations where water temperatures can drop below 59°F (15°C), or if the water flowing through the Hydro Kit heat exchanger has the

potential to freeze, an antifreeze agent such as methanol, ethylene glycol, or propylene glycol must be added to the water circuit. Consult the

Hydro Kit system design engineer and all applicable local, state, and federal codes.

To add the right amount of antifreeze:

• Calculate the approximate volume of water in the system.

• Add antifreeze solution to the Hydro Kit water circuit.

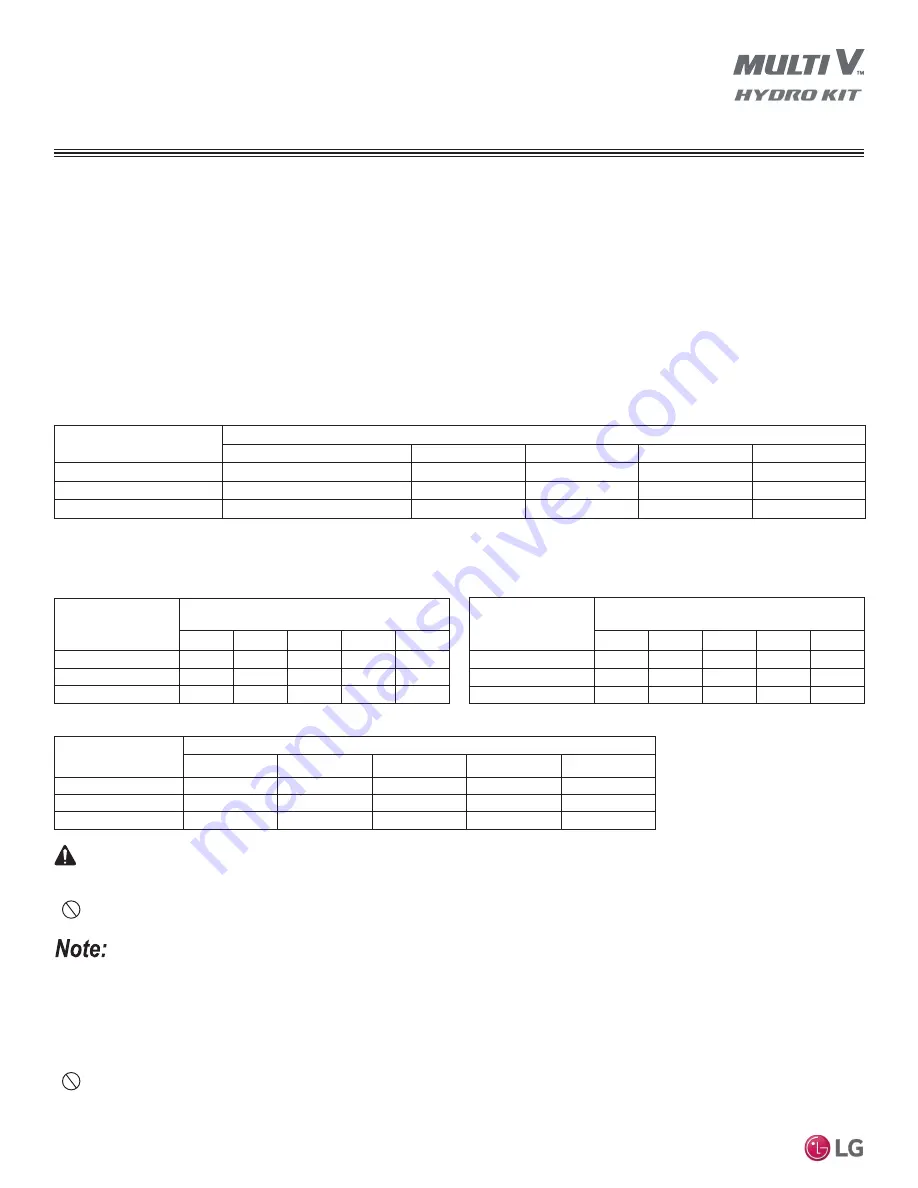

Table 13: Antifreeze Type and Minimum Temperature for Freeze Protection

Type

Minimum Temperature for Freeze Protection

59°F - 23°F (+15°C to -5°C)

14°F (-10°C)

5°F (-15°C)

-4°F (-20°C)

-13°F (-25°C)

Methanol

6%

12%

16%

24%

30%

Ethylene Glycol

12%

20%

30%

-

-

Propylene Glycol

17%

25%

33%

-

-

Type

Antifreeze Concentration Level

(% by Weight)

10%

20%

30%

40%

50%

Methanol

0.998

0.997

0.995

0.993

0.992

Ethylene Glycol

0.996

0.991

0.987

0.983

0.979

Propylene Glycol

0.993

0.987

0.980

0.974

0.968

Type

Heating Antifreeze Concentration Level

(% by Weight)

10%

20%

30%

40%

50%

Methanol

0.995

0.990

0.985

0.979

0.974

Ethylene Glycol

0.993

0.985

0.977

0.969

0.961

Propylene Glycol

0.966

0.973

0.960

0.948

0.935

Table 14: Cooling Capacity Correction by % Antifreeze Chart.

Table 15: Heating Capacity Correction by % Antifreeze Chart.

Table 16: Water Pressure Drop Correction Factors.

Type

Antifreeze Concentration Level (% by Weight)

10%

20%

30%

40%

50%

Methanol

1.023

1.057

1.091

1.122

1.160

Ethylene Glycol

1.024

1.068

1.124

1.188

1.263

Propylene Glycol

1.040

1.098

1.174

1.273

1.405

The antifreeze will reduce the ability of the Hydro Kit to exchange heat energy, and this reduction must be taken into account. See tables

below for cooling and heating capacity and water pressure drop correction factors. See also the Hydro Kit Engineering Manual.

• Follow all notes in this section before adding antifreeze to the Hydro Kit water circuit. Follow all local, state, and federal laws pertaining to

the use and handling of antifreeze.

• Use only one of the listed antifreeze solutions.

• Pressure drop and performance decreases when antifreeze is used.

• Corrosion can still occur when using antifreeze. Add corrosion inhibitor.

• Periodically check antifreeze concentration to maintain the correct percentage levels.

•

If the Hydro Kit is to be used in cooling applications, antifreeze must be added to the water circuit to prevent freezing and burst pipes.

After the antifreeze is added to the water circuit, set DIP Switch No. 2 to ON (on the Hydro Kit PCB DIP Switch Group 3), and disconnect

the Short Key. See the Hydro Kit DIP Switch setting pages in the Pre-Commissioning section for information.

• Follow all warnings before adding antifreeze to the Hydro Kit water circuit. Follow all local, state, and federal laws pertaining to the use and

handling of antifreeze. If not, it will result in physical injury due to toxic exposure.

•

Do not touch the antifreeze during installation or operation. It will result in physical injury due to toxic exposure.

WARNING