Summary of Contents for MB-392AA

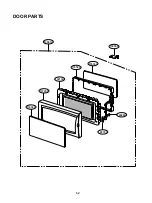

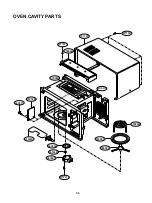

Page 20: ...6 2 13581A 14970A 14026A 13552A 13536A 15006A 13213A 13720D 13352A DOOR PARTS ...

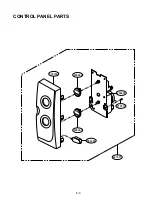

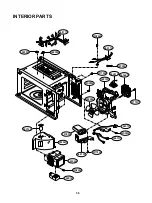

Page 21: ...6 3 23572A 249402 26549T 24781T WTP015 249401 969201 CONTROL PANEL PARTS ...

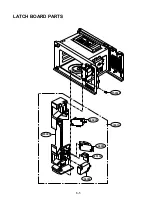

Page 23: ...6 5 466003 466001 43501A 43500A 44510A 466002 WSZ085 LATCH BOARD PARTS ...

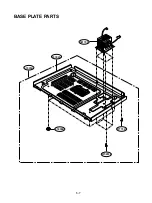

Page 25: ...6 7 56170D 63302A 63303A WTT021 WSZ002 65006B BASE PLATE PARTS ...