16 INSTALLATION

Installing the Anti-tip Device

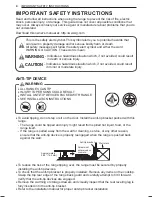

Anti-tip

bracket

Wall plate

Screw must

enter wood or

concrete

The anti-tip bracket is packaged with an installation

template. The instructions include necessary

information to complete the installation. Read and

follow the range installation instruction sheet.

WARNING

•

Range must be secured with an approved

anti-tip device.

•

The range could be tipped by standing, sitting

or leaning on an open door if the range or

anti-tip device is not properly installed.

•

After installing the anti-tip device, verify that it is

in place by carefully attempting to tilt the range

forward.

•

This range has been designed to meet all

recognized industry tip standards for all normal

conditions.

•

The installation of the anti-tip device must meet

all local codes for securing the appliance.

•

The use of this device does not preclude tipping

of the range when not properly installed.

Optional Rear Filler

If the counter does not bridge the opening at the rear

wall the rear filler kit, that is provided with the slide in

range, will be needed.

NOTE

If the countertop depth is greater than 25" there

will be a gap between the filler kit and the back

wall.

If the countertop depth is less than 24", the control

panel will not sit flush with the countertop.

Installing the Rear Filler

1

Using a screwdriver, remove the upper four

screws that attach the rear bracket and loosen

the lower two screws.

2

Place the rear filler on the rear bracket.

3

Tighten the two lower screws on the rear

bracket. Insert one of the screws removed in

step 1 in the slot at each end of the rear filler.

4

Store the remaining two screws with these

instructions for future use.

Providing Adequate Gas

Supply

Your range is designed to operate at a pressure of

5" of water column on natural gas or 10" of water

column on LP.

Make sure you are supplying your range with the type

of gas for which it is configured.

This range is convertible for use on natural or LP gas.

When using this range on LP gas, conversion must

be made by a qualified LP installer before attempting

to operate the range.

For proper operation, the pressure of natural gas

supplied to the regulator must be between 5" and 13"

of water column.

For LP gas, the pressure supplied to the regulator

must be between 10" and 13" of water column. When

checking for correct operation of the regulator, the

inlet pressure must be at least 1" more than the

operating (manifold) pressure as given above.

The pressure regulator located at the inlet of the

range must remain in the supply line regardless of

which type of gas is being used.

A flexible metal appliance connector used to connect

the range to the gas supply line should have an I.D.

of

5

/

8

" and a maximum length of 5 feet. In Canada,

flexible connectors must be single wall metal

connectors less than 6 feet in length.